Aluminum Stacked Fin Heat Sink with Heat Pipe Introduction

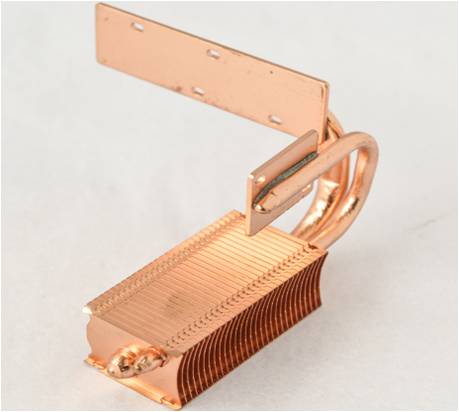

Stacked fin heat sink is an ideal air cooling solution for high-power forced convection applications in mass production. The stacked fin heat sink consists of a series of individual metal sheets, which are stamped, folded, and pulled together using an interlocking function. The length and gap of the fins can be changed by using different stamping dies. The fins can be closed and stacked to create a fin air duct, or opened according to the application air flow requirements to achieve multi-directional air flow.

Heat pipes assemblies increasing the efficiency of heat sink fins. In this situation, the tops of the heat sink fins are dissipating little heat. By connecting the tops of the heat sink fins to the heat sink base with heat pipes, additional heat is carried to inefficient areas, thereby greatly increasing the performance.

Aluminum Stacked Fin Heat Sink with Heat Pipe Process:

1. Stack fin by punch machine, then nickel plated

2. Extruded aluminum base plate, then nickel plated

3. Produce heat pipe, finish anti-oxidation

4. Solder stack fin, base plate and heat pipe by reflow oven

5. Thermal test

6. Degrease

7. Assemble fan and aluminum frame

8. Pack and ship

PT can customize stacked fin heat sink with heat pipe based on your thermal requirement and application. More important, we can design stacked fin heat sink and run simulation to find the best and cost reasonable solution for your application.

+86-18902844286

+86-18902844286

E-mail

E-mail