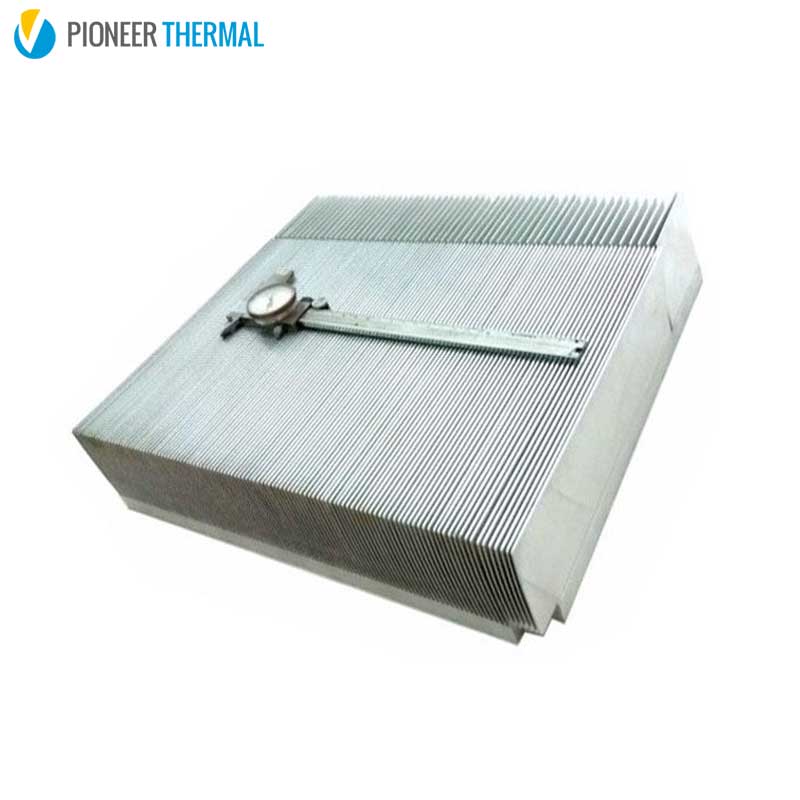

Skived Fin Heatsink Introduction

Skived fin heatsink can be an alternative to extruded heat sinks when looking for a fin density which can’t be achieved by extrusion technology. This skived heatsink is made of AL1060 with good thermal conductivity. Finished with clear anodize.

Pioneer Thermal customized skived fin heat sink advantages:

Reasonable Design: skived fin heat sink has maximize surface area designed in contact with the cooling air. The fins increase the area of the board and thus provide for greater heat transfer

More Safe: skived fin heat sink can reduce the risk of hardware failure due to overheating , using electronic devices will be more safe. Light weight and used in applications where weight is a big concern

Good Thermal Conductivity: skived fin heat sink is made of high quality aluminum, good thermal conductivity, not easy to aging and abrasion resistant, to ensure maximum strength and durability for long lasting usage.

Wide Application: Customized aluminum skived fin heat sink is widely used for greenhouse, computer, Power Transistor, FET, IC, Power Amplifier, Voltage Regulator, MOSFET, SCR etc.

Technical Parameters

| Place of Origin: | Dongguan, China (Mainland) | OEM: | Yes |

| Process: | Skived fin | Temper: | T3-T8 |

| Material: | AL6063 | Shape: | Rectangle |

| Packing: | Paper carton with plywood pallet | Brand Name: | PIONEER THERMAL (PT) |

| Application: | Cooling high-power devices | Certificate: | ISO 9001:2008,ISO 14001:2015, TS16949 |

| Model Number: | PT044 | Tolerance: | 0.05 mm |

| Finish: | Clear andoize | Fin thickness: | 0.25 --2 mm |

| Extra process: | CNC Machining | Size: | Customized |

| Applied Field: | Telecommunication, UPS, inverters, controllers, wind power converters, and SVG | ||

|

AL1060 / AL 6063/ CU1100 Process parameter: |

|||

Heat Sinks Application

+86-18902844286

+86-18902844286

E-mail

E-mail