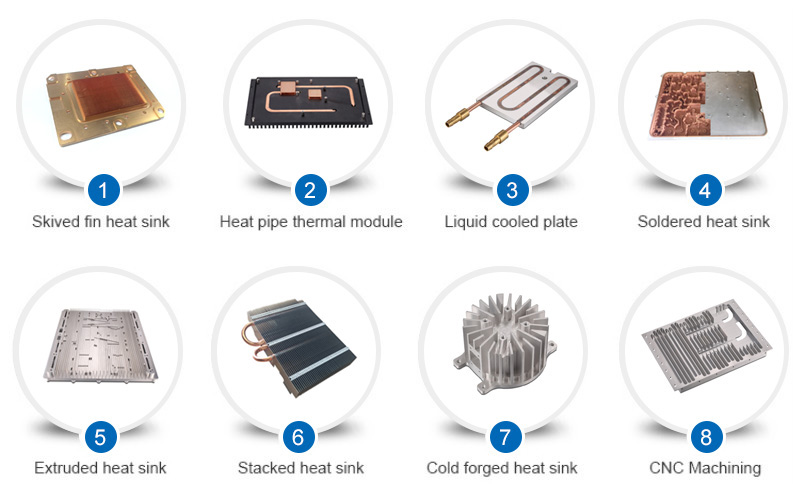

Product Introduction

Extrusion is the most cost effective manufacturing method for producing plate fin and cross cut radiators. The tooling and unit price are the lowest of all mass production processes. The material used for extrusion, A6063, has excellent mechanical properties and surface appearance.

Pioneer Thermal's extrusion heat sink finish can be degrease, nickel plating, gold anodize, pink anodize, blue anoidize etc., contact Pioneer Thermal to find out details.

Extrusion Heat Sink Design Parameter:

| Machine tonnage | Diagonal Line limit | Fin Height/Fin Gap |

| 600T | <120mm | 24 |

| 880T | <130mm | 24 |

| 1000T | <150mm | 22 |

| 1500T | <180mm | 22 |

| 1800T | <200mm | 21 |

| 2500T | <230mm | 21 |

| 2750T | <250mm | 21 |

| 3000T | <320mm | 20 |

| 3600T | <350mm | 20 |

| 4000T | <400mm | 20 |

| 6500T | <540mm | 19 |

| 8000T | <700mm | 16 |

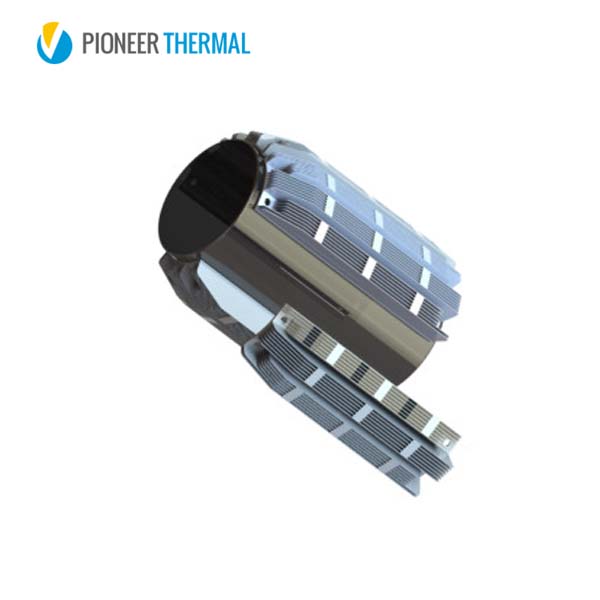

Workshop:

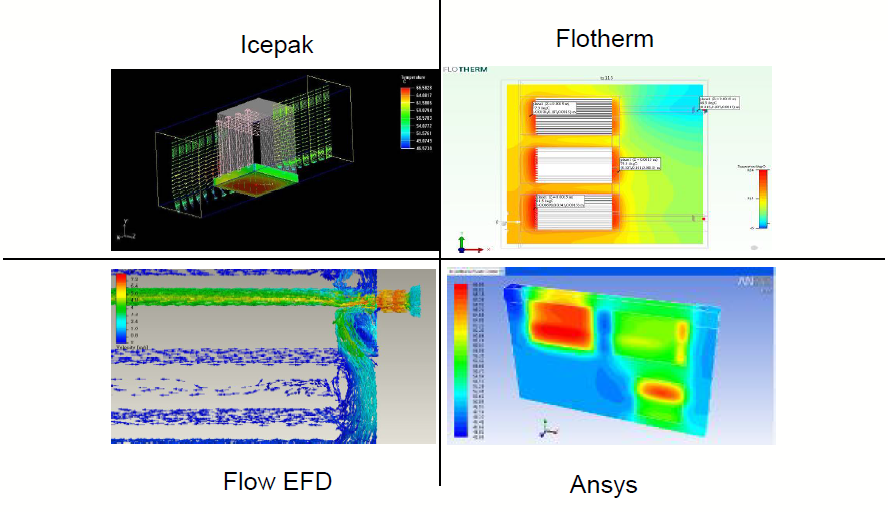

Pioneer Thermal R&D:

Our seasoned professionals can model and critique the thermal implications of your design using Icepak, Flotherm, CFD, Solidworks, ProE, and AutoCAD. We can manage your thermal needs from the conceptual design stage, through prototypes and into production, which enable us to be your “one-stop” shop for quality thermal solutions, delivered on time and at competitive prices.

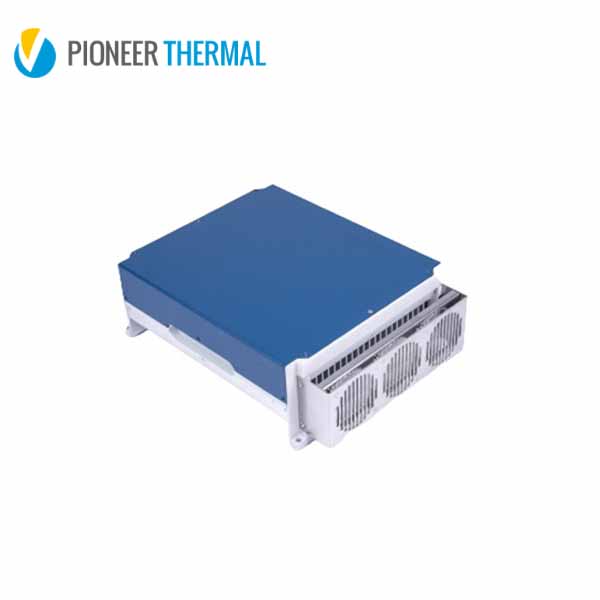

About Pioneer Thermal:

As a heat sink manufacturer in China, Pioneer Thermal is certified with ISO9001, ISO14001 and TS16949, and has a dedicated quality assurance department with full CMM capabilities. We are focused on providing advanced technology, superior customer service and outstanding value to our industry partners.

Our Customers

Most of Pioneer Thermal's heatsinks are customized and widely applied in IPC, server, telecom & communications, infrastructure &power, LED lighting, medical equipment, PV inverter, new energy and other application.

+86-18902844286

+86-18902844286

E-mail

E-mail