Product Introduction

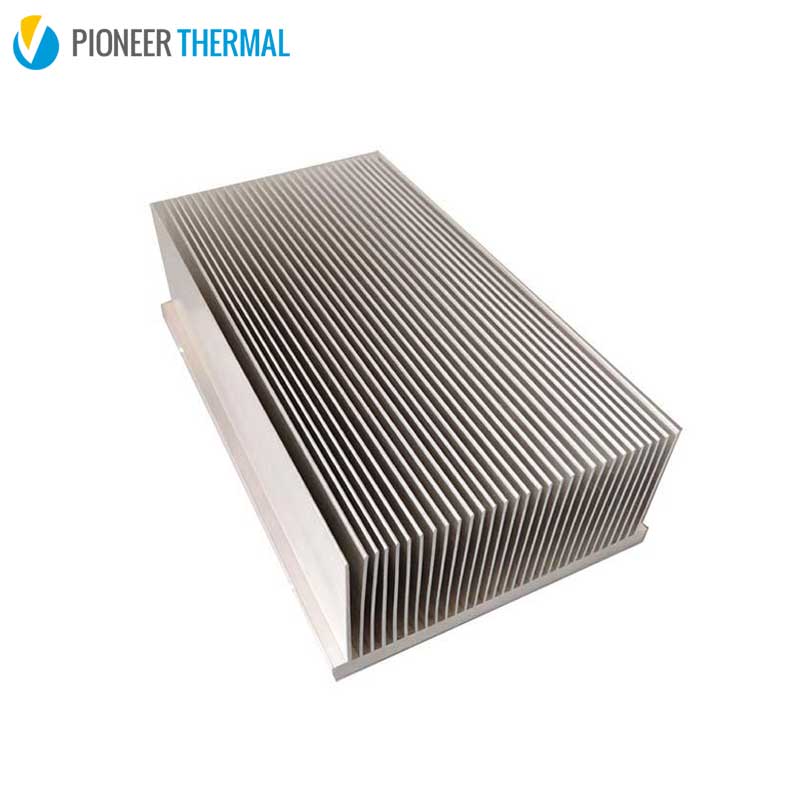

Extrusion heat sinks are the most common heat sinks used today for thermal management. They are made by pushing a hot billet of aluminum through a steel die to form the final shape. The most common aluminum alloy is 6063-T5, but other 6XXX alloys can be used as needed.

Extrusion heat sink process:

Extrusion Heat Sink Design Parameters

|

MACHINE |

|

FIN HEIGHT/FIN GAP |

|

|

FIN HEIGHT |

| 600T | <120mm | 24 | 2750T | <250mm | 21 |

| 880T | <130mm | 24 | 3000T | <320mm | 20 |

| 1000T | <150mm | 22 | 3600T | <350mm | 20 |

| 1500T | <180mm | 22 | 4000T | <400mm | 20 |

| 1800T | <200mm | 21 | 6500T | <540mm | 19 |

| 2500T | <230mm | 21 | 8000T | <700mm | 16 |

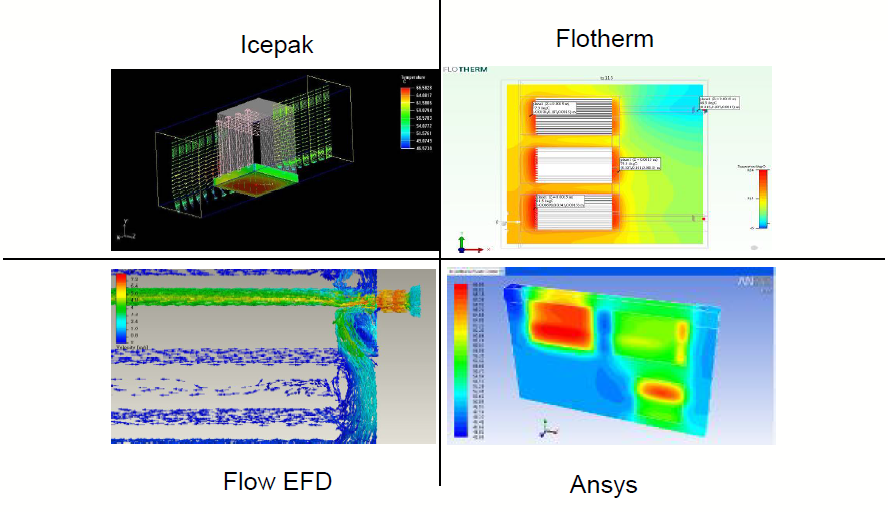

Pioneer Thermal R&D:

About Pioneer Thermal:

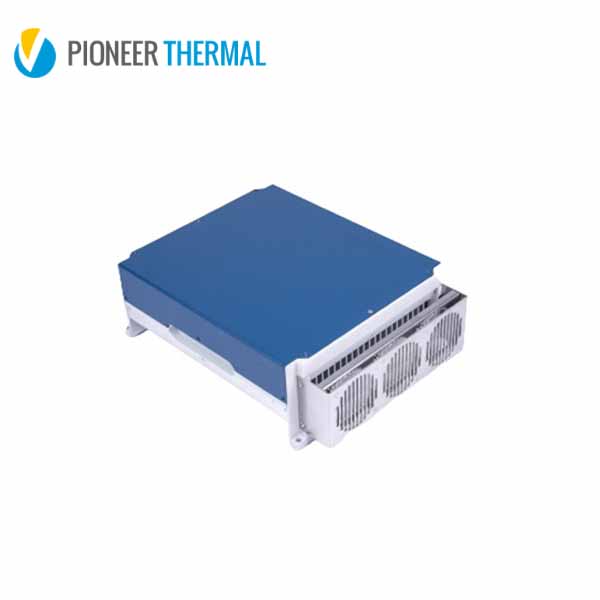

As a heat sink manufacturer in China, Pioneer Thermal is certified with ISO9001, ISO14001 and TS16949, and has a dedicated quality assurance department with full CMM capabilities. We are focused on providing advanced technology, superior customer service and outstanding value to our industry partners.

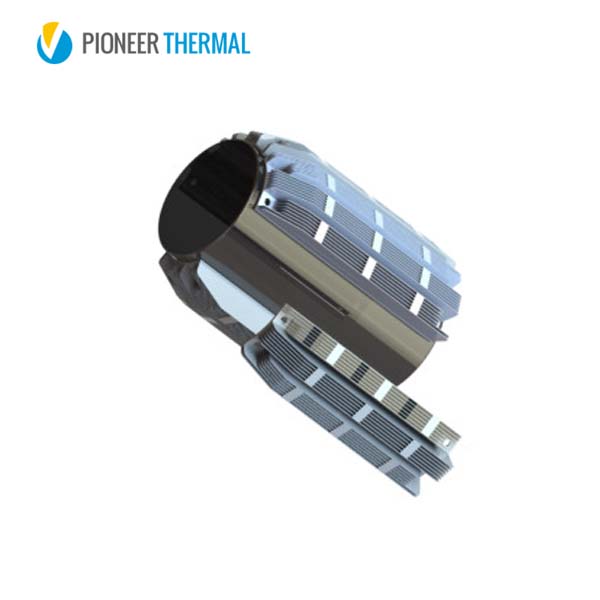

Pioneer Thermal has more than 18 years experience in CNC machining, cold forging heatsinks, cold plate heatsinks, die casting heatsinks, extrusion heatsinks, heatpipe assemblies, skived fin heatsinks, stacked fin heatsinks, folded fin heatsinks etc. If you need any heat sink service, please contact Pioneer Thermal.

+86-18902844286

+86-18902844286

E-mail

E-mail