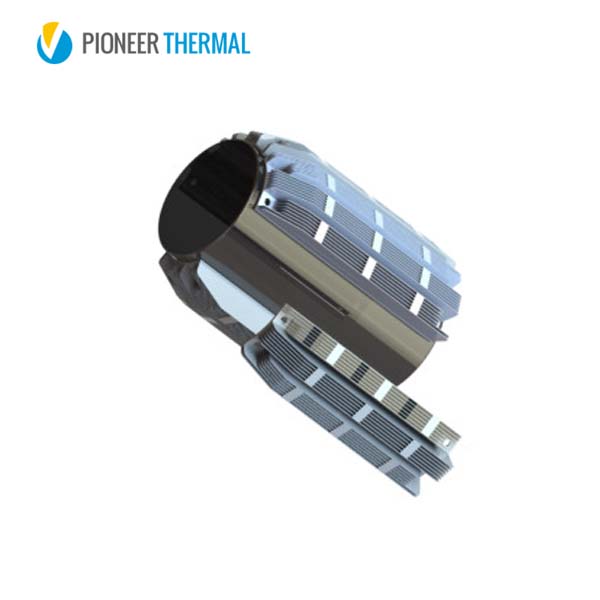

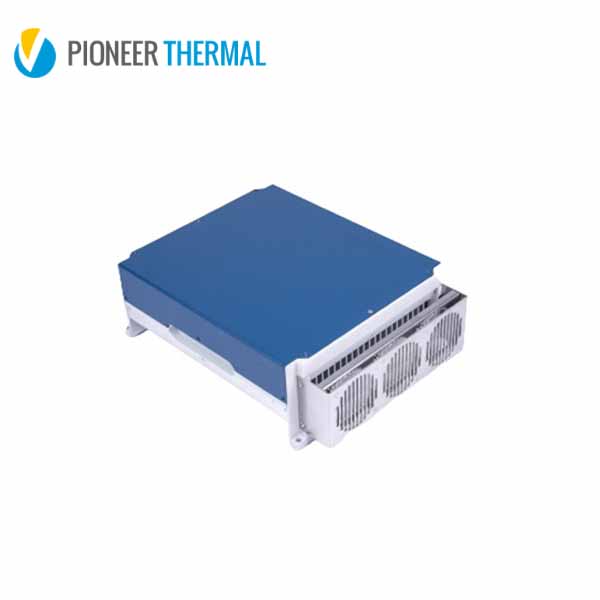

5G Heat Sink With Extrusion Process

Extrusion Heat Sink Common Process:

Here is the CNC tolerance limits when the extrusion heat sink need CNC machining process:

| Flatness | 0.02mm within 100*100mm |

| Roughtness | Ra 0.4μm |

| Hole Pitch | +/- 0.05mm |

| Diameter | +/- 0.02mm |

| Shape | +/- 0.05mm |

| Max. CNC dimension | 1270*750*600mm |

Pioneer Thermal Quality Assurance:

Quality Inspection Tool of Pioneer Thermal:

| Heat sink dimension | |||||

| CMM | Projector | ||||

| Heat sink performance | |||||

| Salt Spray Tester | Pressure Tester | Clip Force Tester | Drop Tester | Helium Leakage Tester | |

| Heat sink reliability | |||||

| Wind Tunnel | On Line Thermal Tester | HP Qmax Tester | HP Delta T Tester | Thermal Shock | High Temperature Aging Chamber |

Pioneer Thermal R&D

Pioneer Thermal's seasoned professionals can model and critique the thermal implications of your design using Icepak, Flotherm, CFD, Solidworks, ProE, and AutoCAD. We can manage your thermal needs from the conceptual design stage, through prototypes and into production, which enable us to be your “one-stop” shop for quality thermal solutions, delivered on time and at competitive prices.

About Pioneer Thermal:

As a heat sink manufacturer in China, Pioneer Thermal is certified with ISO9001, ISO14001 and TS16949, and has a dedicated quality assurance department with full CMM capabilities. We are focused on providing advanced technology, superior customer service and outstanding value to our industry partners.

+86-18902844286

+86-18902844286

E-mail

E-mail