Introducción del producto

Proceso de manufactura

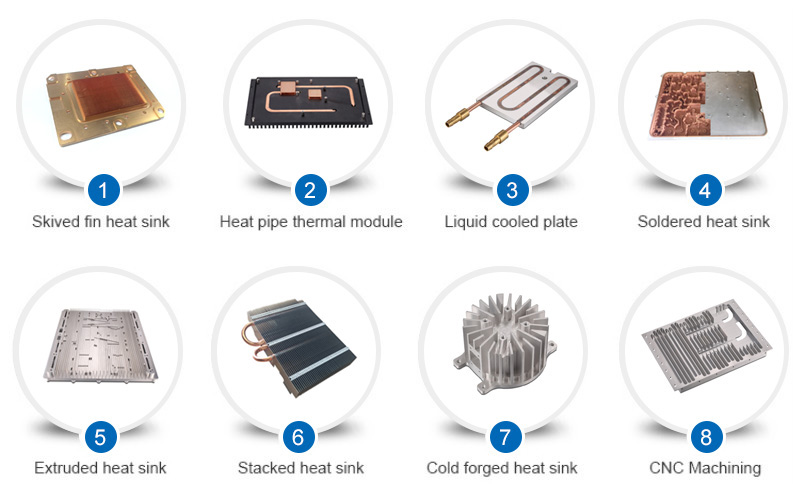

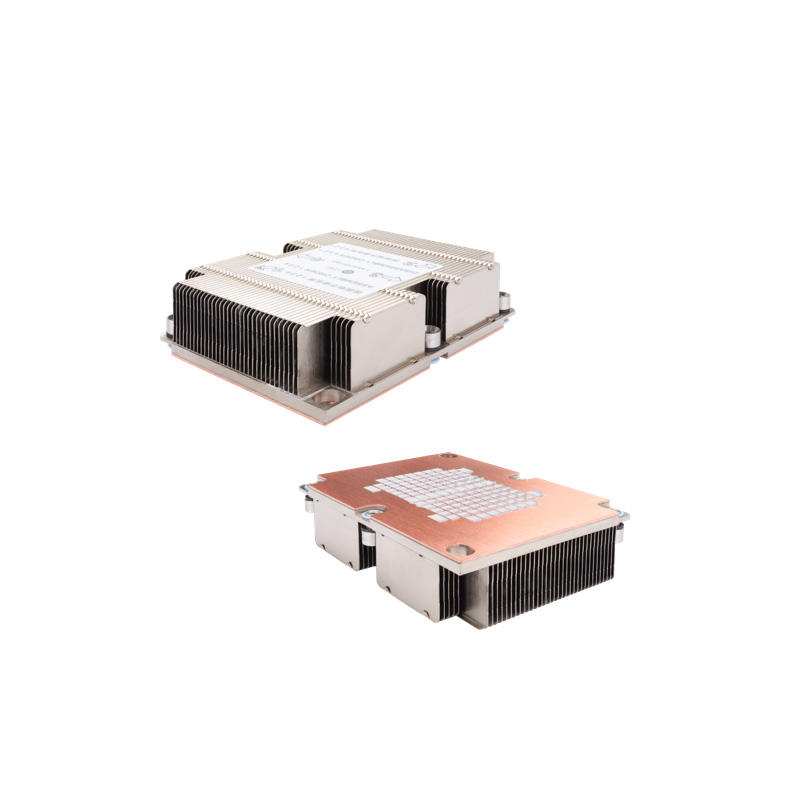

Stacked fin heatsinks solutions offer better performance when compared to typical extrusion heatsinks, due to thinner fin profiles leading to higher surface area and lower pressure drop.

Stacked fin and folded fin heat sinks are manufactured by stamping sheets of rolled aluminum or copper into a tightly formed array of fins. A progressive tool is used in the stamping process to cut features and then interlock the fins together. Snapped fin heat sinks are most commonly integrated with heat pipes at the condenser end where they are used to cool the heat pipes, thus enabling the phase change.

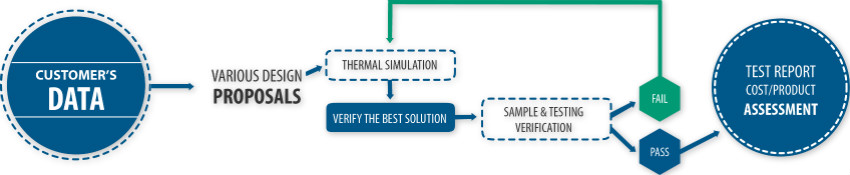

Design Flowchart

Custom Heat pipe Heat sink, Copper heat sink Supplier, heatsink OEM service.

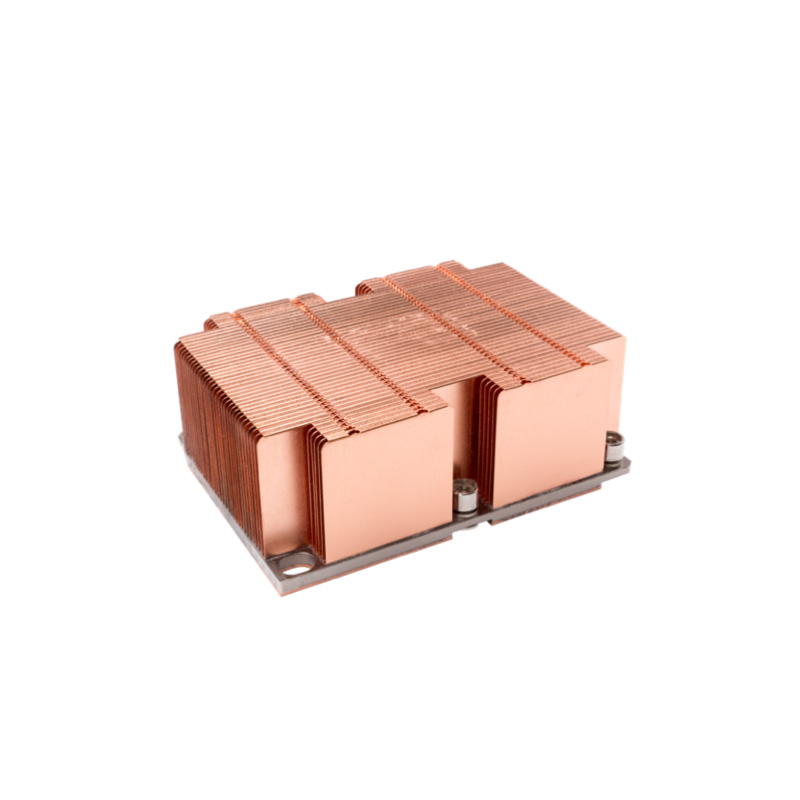

Parámetros técnicos

|

Item |

Description |

|

Dimension |

89.6*88*29mm |

|

Material |

CU Skive fin |

|

Fin Spec |

Thick=0.3mm、Pitch=1.4mm、63Fin |

|

Screw Type |

M3*0.5 |

|

Ring Type |

E-ring |

|

TIM Type |

BN-G560(35*35mm) |

|

Hole Location |

75*75mm |

|

Fan Spec |

7015-5000RPM-49dB |

|

Performance |

95W |

Nuestros clientes

Our most of products are customized and widely applied in IPC,server,telecom & communications infrastructure &power,LED lighting,medical equipment and other products.

Métodos de envío

Any cold forging heatsinks services, please contact Pioneer Thermal. We'll reply you within 12 hours.

Help your design design team to improve the part for manufacture.(design refine/process optimize/cost reasonable)

English

English Español

Español Deutsch

Deutsch Français

Français 日本語

日本語

+86-18902844286

+86-18902844286

E-mail

E-mail