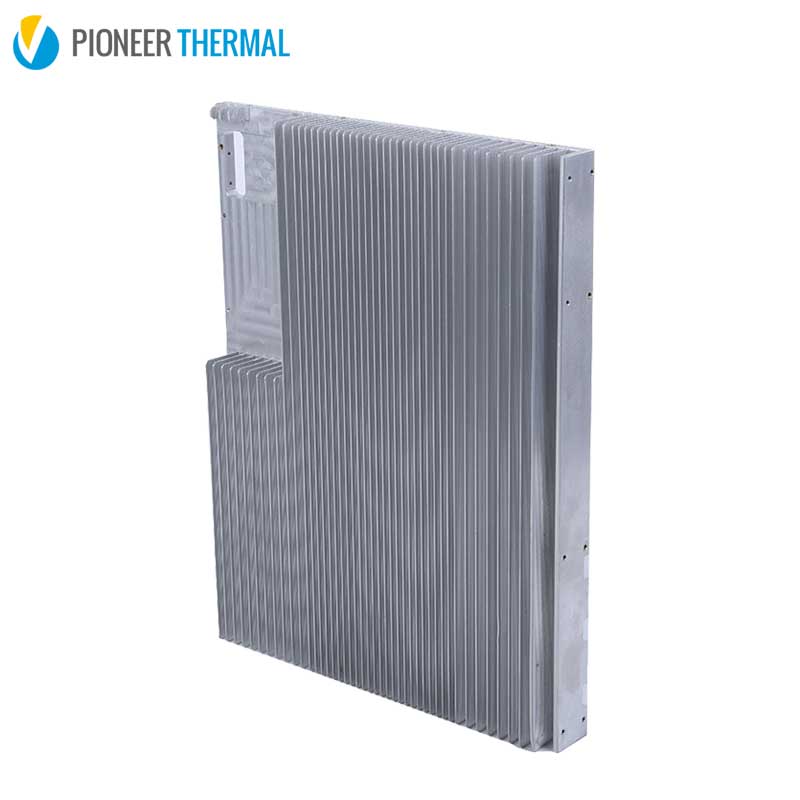

Product Introduction

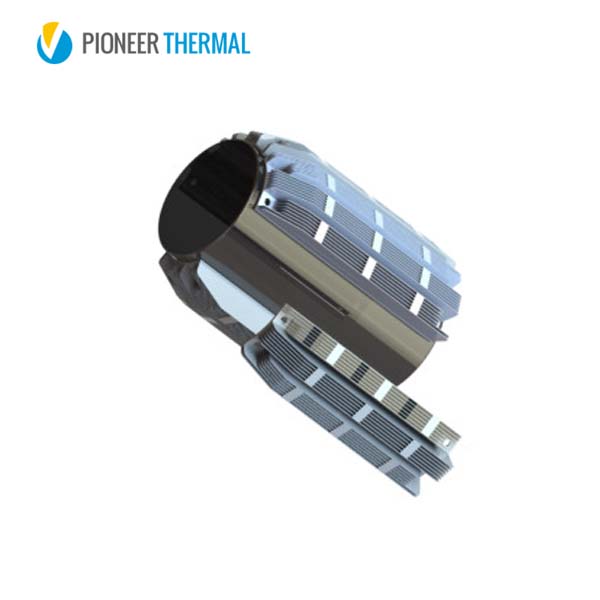

Many heat transfer problems can be solved using conventional Aluminium Extruded Heat Sinks, put an aluminum round bar on the cutting table, and then passed to the aluminum bar heating furnace by conveyor belt in turn. Before extrusion, the aluminum bar needs to be heated to a certain temperature (480˚C), and the alloying elements reach the melting point temperature, at which the alloying elements, usually magnesium and silicon, start to melt.

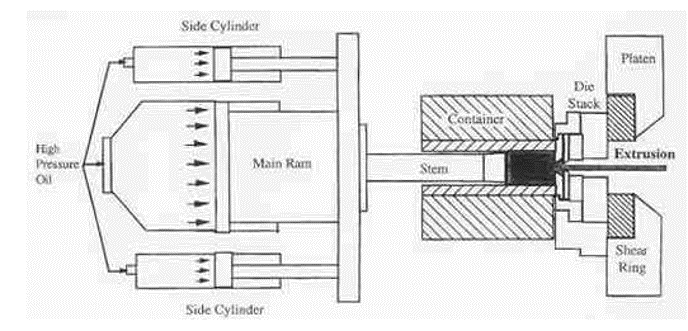

The extrusion machine uses the principle of hydraulic pressure in the ingot barrel to extrude the softened aluminum material through the die, and the shape of the die determines the shape of the formed aluminum material.

Extruded heatsink process:

Workshop

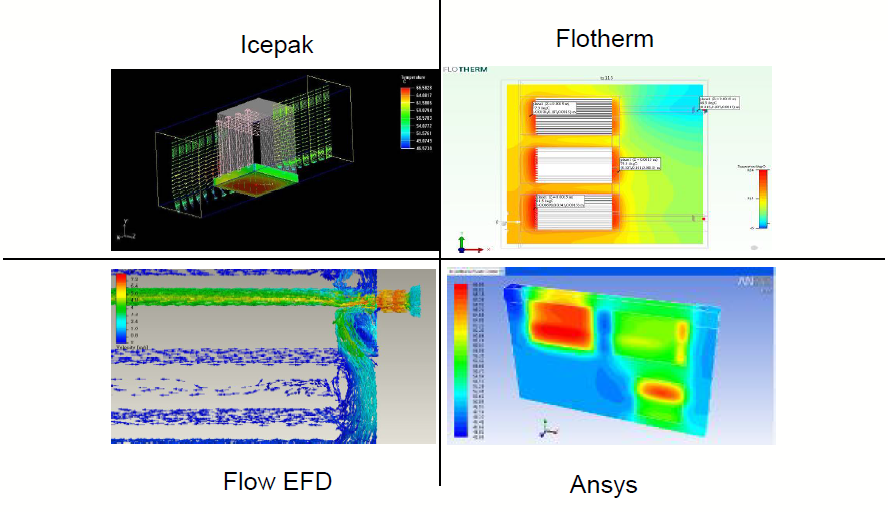

Pioneer Thermal R&D:

About Pioneer Thermal:

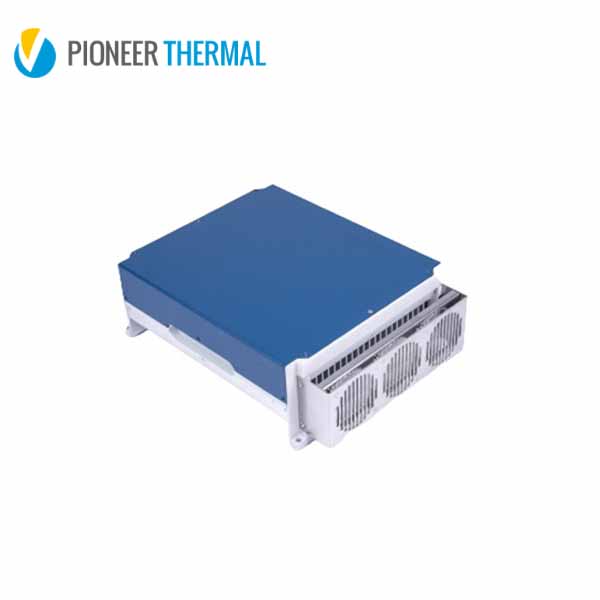

As a heat sink manufacturer in China, Pioneer Thermal is certified with ISO9001, ISO14001 and TS16949, and has a dedicated quality assurance department with full CMM capabilities. We are focused on providing advanced technology, superior customer service and outstanding value to our industry partners.

Our Customers

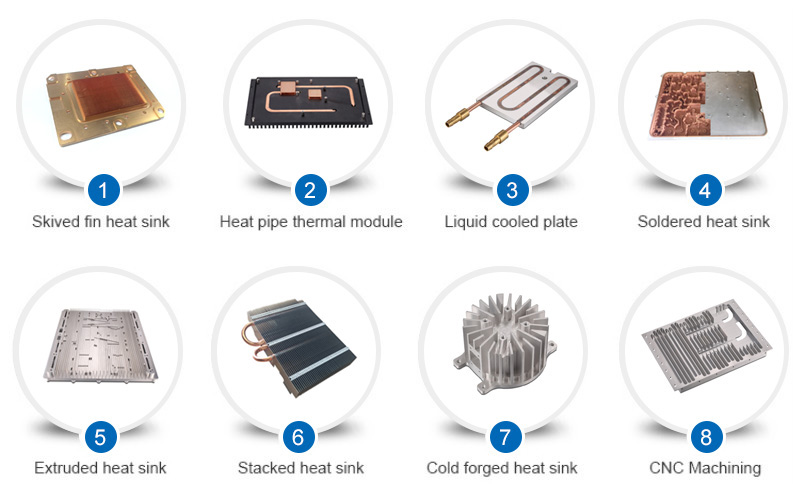

Most of Pioneer Thermal's heatsink are customized and widely applied in IPC,server,telecom & communications infrastructure &power,LED lighting,medical equipment and other products.

+86-18902844286

+86-18902844286

E-mail

E-mail