Product Introduction

The common material that used for pin fin heat sink is AL1070 and CU1100, yes, pin fin heat sink can be made not only of aluminium but also of copper. Pioneer Thermal also developed pin fin heat sink to be made with AL6063 for some certain structure and market.

Pin fin heat sink normally used for LED, camera etc., compare to extrusion heat sink, pin fin heat sink thermal performance is better and heat dissipation area is bigger. Pin fin heat sink surface treatment can be anodize, e-coating, painting, nickel plating, anti-oxidation.

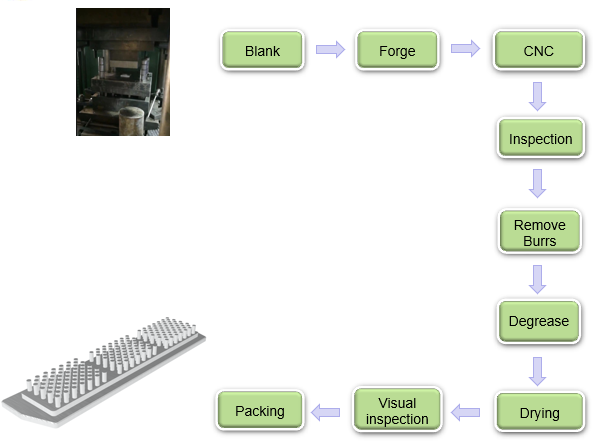

Pin Fin Forging Heat Sink Process:

1. Pin fin heat sink is a blank material at first place

2. Then it will be forged by forge machine

3. CNC machining the needed flatness etcs. for pin fin heat sink

4. Inspection the dimension and surface of the pin fin heat sink, make sure dimension is within specification

5. Remove burrs

6. Surface treatment: degrease, other finishing is also available for pin fin heat sink, like gold anodize, blue anodize, red anodize, black anodize, e-coating etc.

7. Visual inspection: make sure the surface is clean, no stain, scratches etc.

8. Packing and ship to customer

+86-18902844286

+86-18902844286

E-mail

E-mail