Product Introduction

Friction Stir Welded Aluminum Liquid Cooling Plate Advantages:

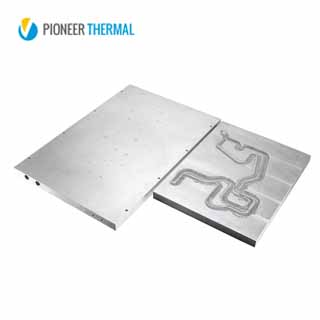

Friction welding is a solid - state welding method, Friction welding compared with traditional welding ,the biggest difference is in the whole welding process, is to keep the increased temperature due to the energy obtained by the metal to be welded below its melting point. That is, the metal is welded under the solid state which is similar to forging under its thermoplastic state.

As compared to conventional welding, friction welding has the advantages of higher-quality welded connections which meet the requirements of seam strength and base material strength, higher welding efficiency, stable quality, better consistency, and the realization of dissimilar metal welds.

Using friction welding for heat sinks can resolve the technical bottleneck of joining two or more materials to form high-aspect-ratio ultra-wide products. Moreover, its tooling cost is lower with a short cycle time and higher stability. Based on the data that has been accumulated by our R&D team in the long run, Pioneer thermal has developed several standard materials and we keep enhancing the database of our standard materials so as to provide our clients with more joint solutions for selection.

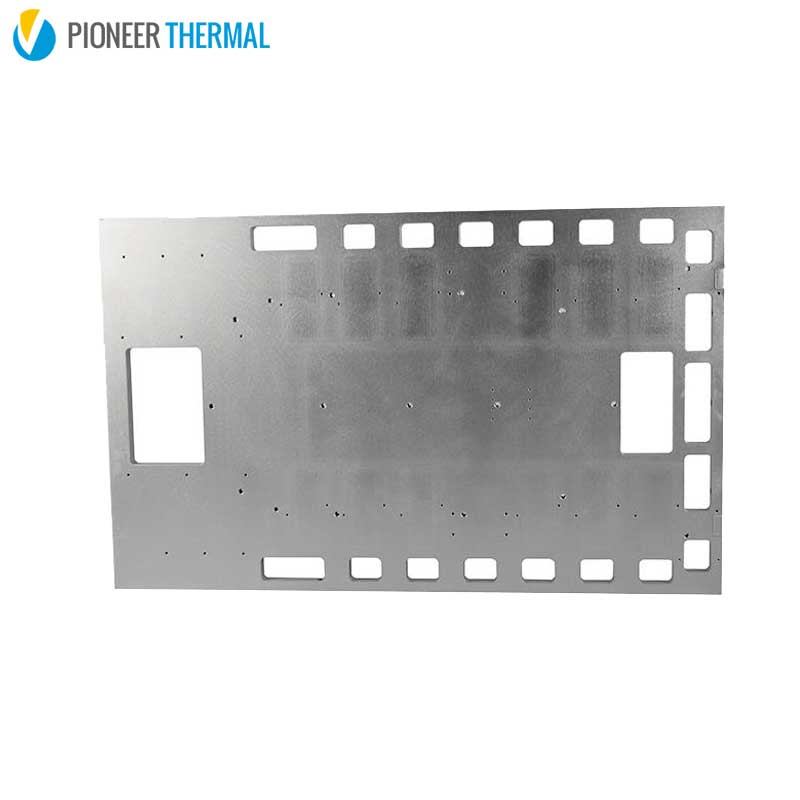

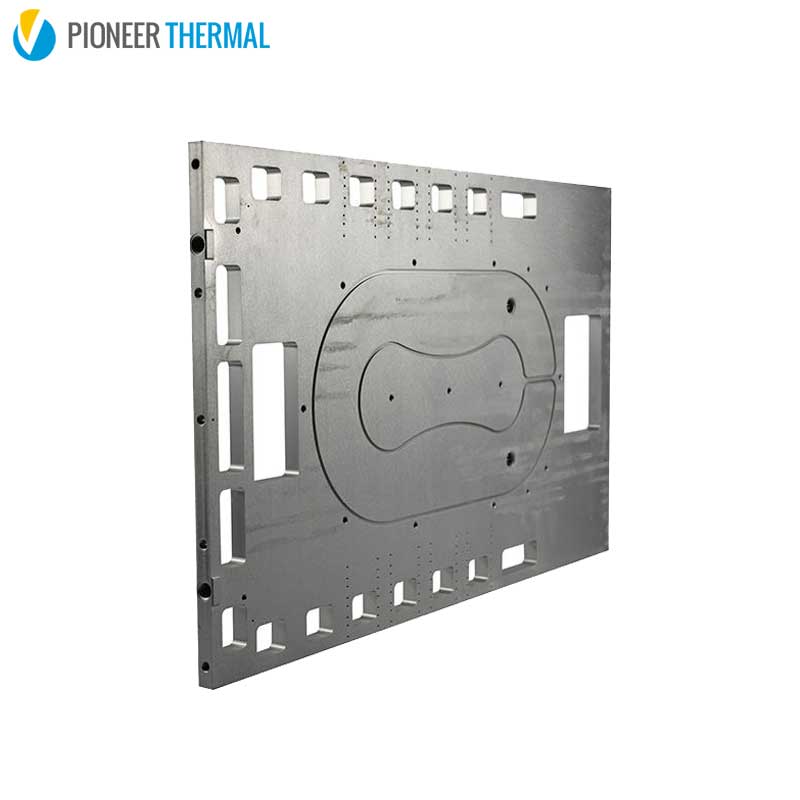

Maximum size of FSW cold plate we can do up to 1000*800mm.

For aluminum FSW cold plate, depth can reach to 25mm

Friction Stir Welding liquid cold plate process:

Available Heat Sink Process Of Pioneer Thermal:

| Main Process | Extrusion | Bonded Fins | Skived Fins | Snapped Fins | Folded Fins | Heat Pipes |

| Cold Forging | Die Casting | FSW cold plate | Gun drill cold plate | Vacuum brazing cold plate | Vapor chamber | |

| Finishing Processes | CNC machining | Drilling | Tapping | Stamping | Anodizing | Screen printing |

| Powder coating | Laser etching | Polishing | Electrophoresis | E-coating | ||

| Finishing Value Added | Embedded fans | Thermal Greases | Screws | Springs | Clips | Embedded heat pipes |

| Phase change materials | Back plates | Gap filler pads | PEMs | Standoffs | Dielectric pads | |

| Compounds | ||||||

Pioneer Thermal Quality Assurance:

Inspection tool of Pioneer Thermal:

| Heat sink dimension | |||||

| CMM | Projector | ||||

| Heat sink performance | |||||

| Salt Spray Tester | Pressure Tester | Clip Force Tester | Drop Tester | Helium Leakage Tester | |

| Heat sink reliability | |||||

| Wind Tunnel | On Line Thermal Tester | HP Qmax Tester | HP Delta T Tester | Thermal Shock | High Temperature Aging Chamber |

Pioneer Thermal R&D:

Our seasoned professionals can model and critique the thermal implications of your design using Icepak, Flotherm, CFD, Solidworks, ProE, and AutoCAD. We can manage your thermal needs from the conceptual design stage, through prototypes and into production, which enable us to be your “one-stop” shop for quality thermal solutions, delivered on time and at competitive prices.

About Pioneer Thermal:

As a heat sink manufacturer in China, Pioneer Thermal is certified with ISO9001, ISO14001 and TS16949 with 7500 square meter facility, and has a dedicated quality assurance department with full CMM capabilities. We are focused on providing advanced technology, superior customer service and outstanding value to our industry partners.

+86-18902844286

+86-18902844286

E-mail

E-mail