Product Introduction

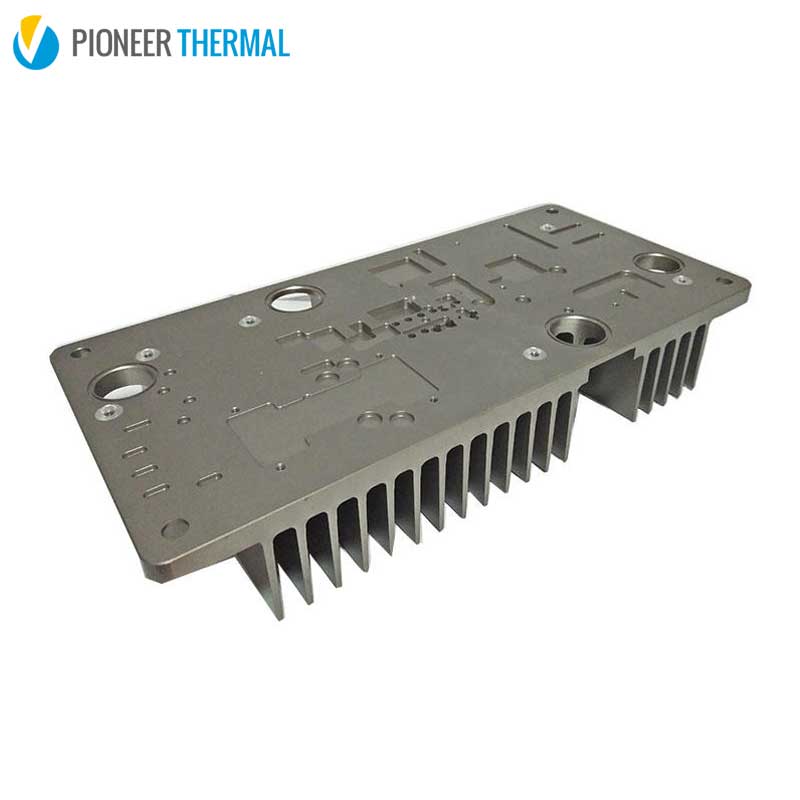

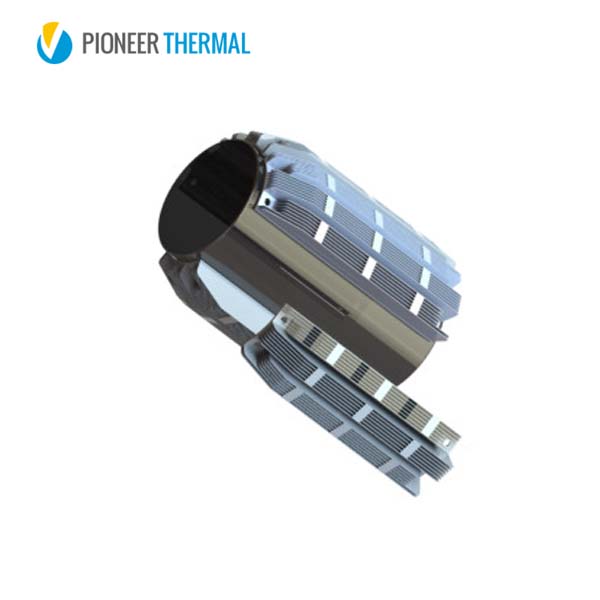

Due to a proven and reliable manufacturing process, extrusion heat sink is the perfect solution for both small and large quantities.

The manufacturing process is the most cost effective compare to other heat sink process, and the tooling is relatively cheap.

Extrusion heat sink process:

Extrusion Heat Sink Design parameter:

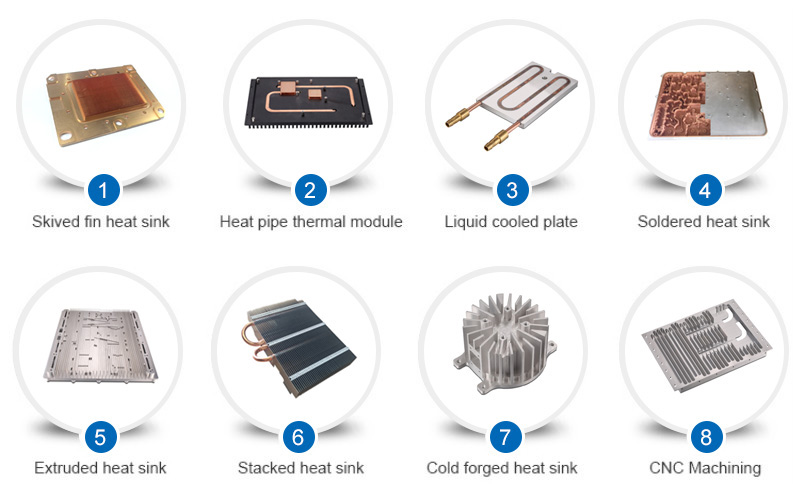

| Machine tonnage | Diagonal Line limit | Fin Height/Fin Gap |

| 600T | <120mm | 24 |

| 880T | <130mm | 24 |

| 1000T | <150mm | 22 |

| 1500T | <180mm | 22 |

| 1800T | <200mm | 21 |

| 2500T | <230mm | 21 |

| 2750T | <250mm | 21 |

| 3000T | <320mm | 20 |

| 3600T | <350mm | 20 |

| 4000T | <400mm | 20 |

| 6500T | <540mm | 19 |

| 8000T | <700mm | 16 |

Heat Sink Process:

|

Tooling cost Extrusion Bonded Fins Cold Forging Die Casting Folded Fins Heat Pipes Skived Fins Snapped Fins

|

Finishing Processes CNC machining Drilling Tapping Stamping Anodizing Screen printing Powder coating Laser etching Polishing |

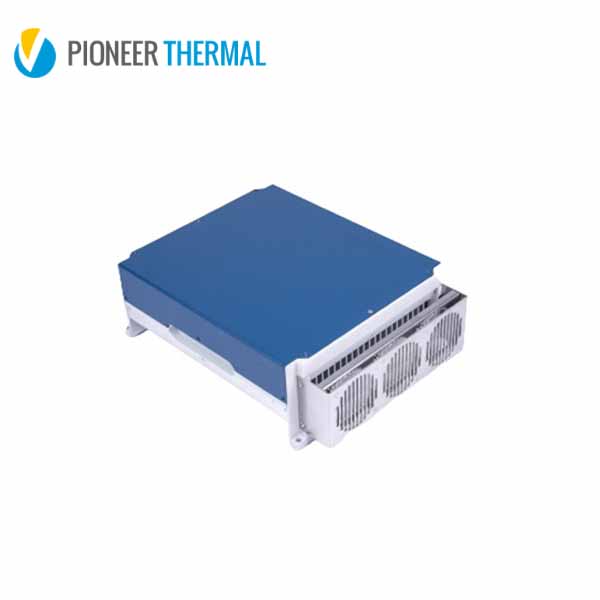

Finishing Value Added Embedded fans Thermal Greases Screws Springs Clips Embedded heat pipes Phase change materials Back plates Gap filler pads PEMs Standoffs Dielectric pads Compounds |

About Pioneer Thermal:

As a heat sink manufacturer in China, Pioneer Thermal is certified with ISO9001, ISO14001 and TS16949, and has a dedicated quality assurance department with full CMM capabilities. We are focused on providing advanced technology, superior customer service and outstanding value to our industry partners.

Our Customers

Most of Pioneer Thermal's heat sinks are customized and widely applied in IPC,server,telecom & communications infrastructure &power,LED lighting,medical equipment and other products.

+86-18902844286

+86-18902844286

E-mail

E-mail