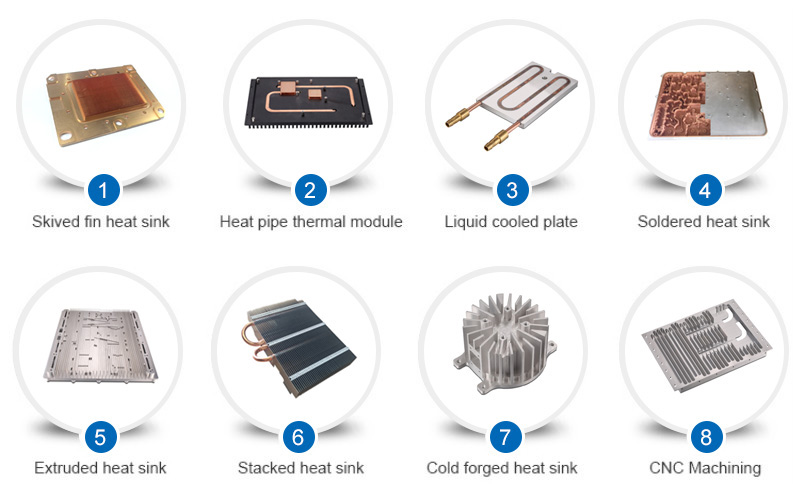

Aluminum Extrusion Heat Sink Introduction

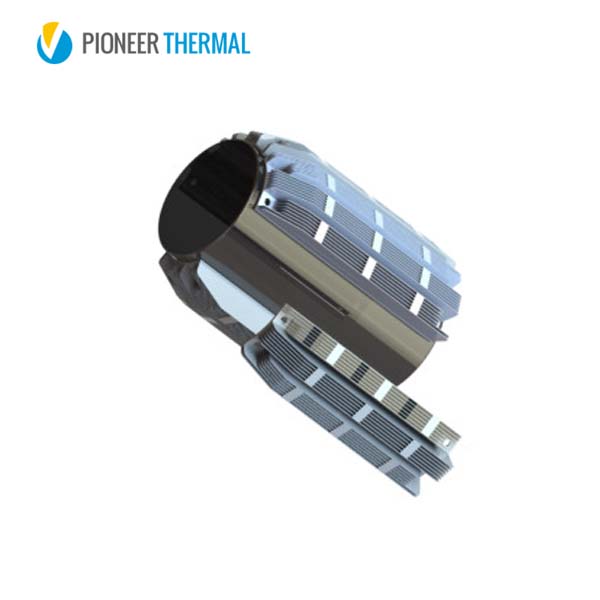

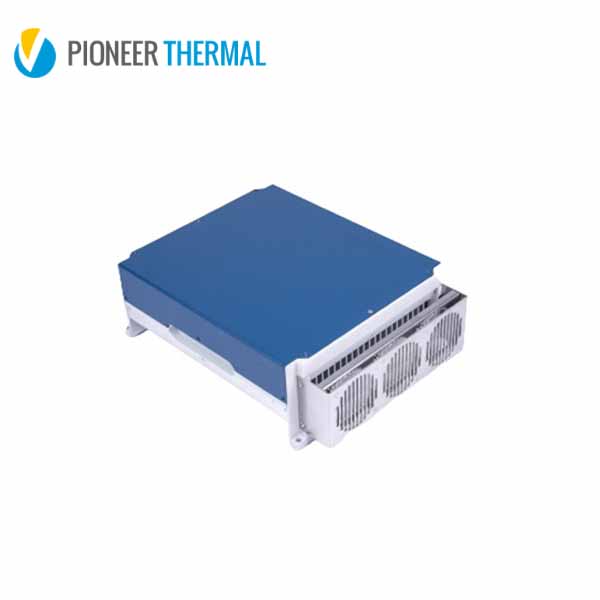

Extruusion heat sink are generally high power cooling elements and heat dissipation systems. Pioneer Thermal can provide a reliable solution for natural convection environment based on the existing mature aluminum extrusion profile heat sink technology. Aluminum extrusion molding is achieved through a die, which allows for complex heat dissipation teeth structures. These complex heat sinks increase the surface area of the heat sink while reducing the cost and time of aluminum block processing.

Aluminum Extrusion Heat Sink Advantages:

1. More efficient than stamped heat sinks

2. More cost effective than machining

3. A wide range of standard shapes and sizes available

4. Easy customization to achieve lighter than copper with significant advantages

5. MAX CLIP fastener system requires no mounting hardware or tools

Aluminum Extrusion Heat Sink Details:

This aluminum extrusion heat sink process is:

1. Extruded single part.

2. Press fit the single part together

3. CNC machining the top and base to achieve certain flatness

4. Surface treatment-degrease

5. Inspection, pack and ship.

We can customize the aluminum extrusion heat sink based on your requirement to suit your application.

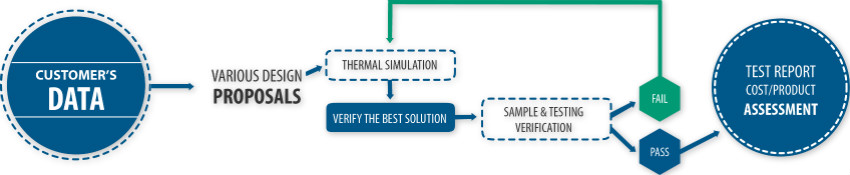

Design Flowchart

Customers

China Heat Sink, Most of our products are customized and widely applied in IPC, server,telecom & communications infrastructure &power,LED lighting,medical equipment and other products.

+86-18902844286

+86-18902844286

E-mail

E-mail