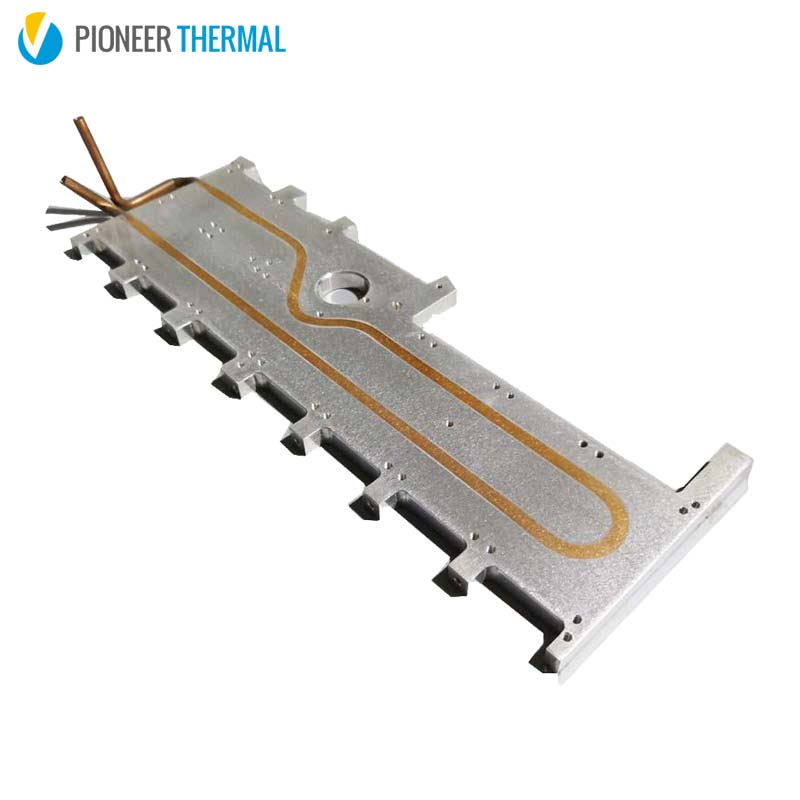

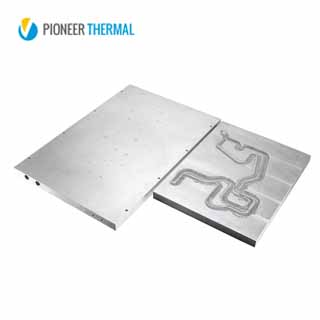

Product Introduction

The water cooling plate made using buried welding technology can effectively avoid the leakage risk of the infusion pipeline, and the liquid flow is large, the conduction heat resistance is very low, and the device can be installed on the water cooling heat sink. we are providing you with thermal design, structural design, pipework assembly design of cooling plate and aluminium water cooling heat sink and one-stop supplementary services.

Water cooling plate Technical Parameters

| Place of Origin: | Dongguan, China (Mainland) | OEM: | Yes |

| Process: | Profiles Extruding | Temper: | T3-T8 |

| Material: | AL6063T5 | Shape: | Square |

| Packing: | Standard Export Packing | Brand Name: | PIONNER THERMAL |

| Application: | IGBT inverter | Certificate: | ISO 9001:2008,ISO 14001:2004 |

| Model Number: | PT008 | Tolerance: | 0.01 mm |

| Finish: | Degreasing, Anodizing,Sand Blasting, | Quality control: | 100% thermal test |

| Extra process: | Cutting + CNC Machining(Milling, Drilling,Tapping) | Size: | 142(W)*71.5(H)*200(L)mm, or custom design |

| Max Aspect Ratio | More than 20 times aspect ratio heat sink can be extruded by 800 tons--5000 tons extruding machine by the most advanced technology | ||

| Max Width | Ultra wide extruded heat sink can be made by our unique friction welding technology | ||

| Sample Service | Samples with differernt sizes are availabe for prototypes test within 1-2 week | ||

| Production Process | Profiles Extrution---Cutting---CNC Machining(Milling, Drilling,Tapping), Deburring, Cleaning, Inspecting, Packing | ||

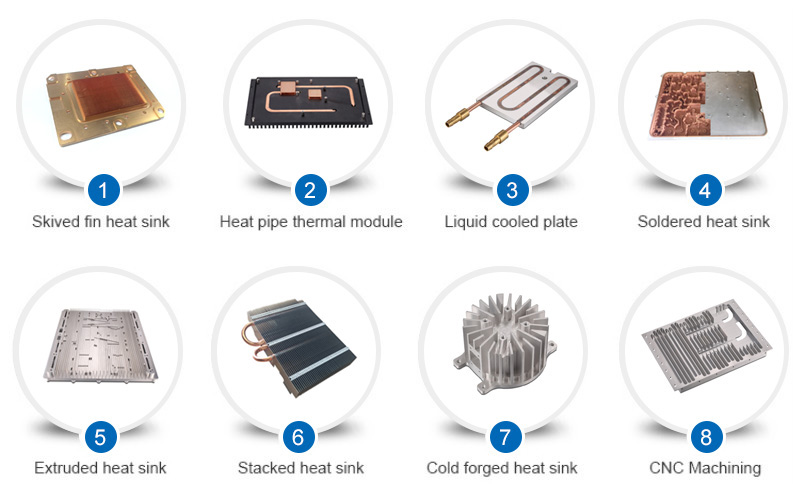

Our Customers

Our most of heat sinks are customized and widely applied in IPC,server,telecom & communications infrastructure &power,LED lighting,medical equipment and other products.

Shipping Methods

Any custom heat sinks services, please contact Pioneer Thermal. We'll reply you within 12 hours.

Help your design design team to improve the part for manufacture.(design refine/process optimize/cost reasonable)

+86-18902844286

+86-18902844286

E-mail

E-mail