Product Introduction

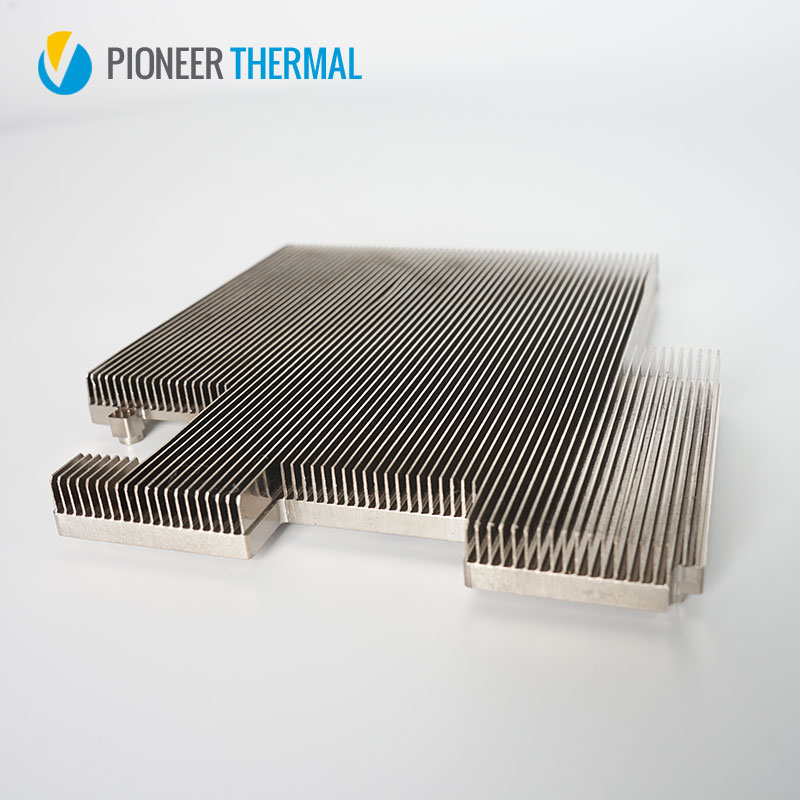

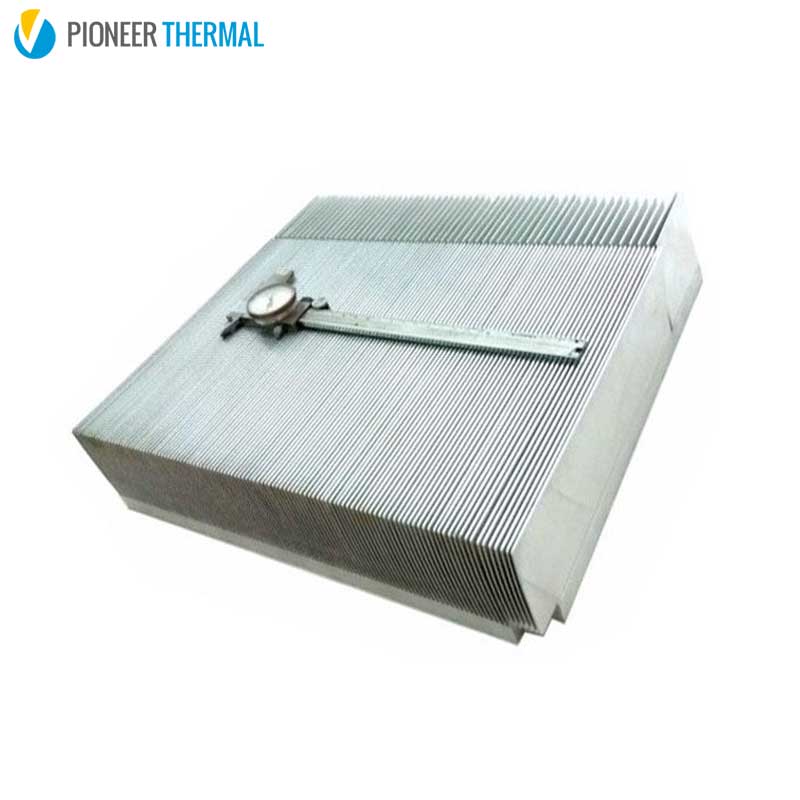

Skived Fin heat sinks can be an alternative to extruded heat sinks when looking for a fin density which can’t be achieved by extrusion technology. Skived heat sinks can be manufactured from either copper or aluminum and usually have 0.5 (0.020”) thick fins.

Technical Parameters

|

Place of Origin |

Dongguan China |

Material |

AL1060, copper is also available |

|

Shape |

Customized |

Sample |

Available

|

|

Model number |

SK-2 Skived fin |

Process |

Skived |

|

Item |

Heatsinks |

Fin thickness |

0.25 --2 mm |

|

Finish |

Degrease, other finish is available |

Certificate |

ISO9001,ISO14001, TS16949 |

|

Extra process |

CNC maching |

size |

Customized |

|

Length |

Less than 2m |

OEM |

Yes |

|

Application field |

Telecommunication, UPS, inverters, controllers, wind power converters, and LED lighting |

||

Skiving fin process video:

Skived fins are achieved by a knife tool that literally shaves fins up from an extruded aluminum or copper base. This process of slicing and then standing the fins up one at a time can create an extremely high fin-to-gap aspect ratio. The top of the fins are then cut to maintain a uniform height. This increased surface area drastically improves the thermal performance in forced airflow environments.

Skived fin heat sinks are commonly found in the following applications:

Computers and electronic components

Telecommunication equipment

Industrial equipment and components

Lighting lamps and household appliances industry

Automotive components

As a heat sink manufacture, Pioneer Thermal has more than 18 years experience in Skiving fin heat sink production. Our focus has always been to provide superior customer service in the high quality cost-effective custom heat sink area. Any custom heatsink and standard heatsink demand, please contact Pioneer Thermal.

+86-18902844286

+86-18902844286

E-mail

E-mail