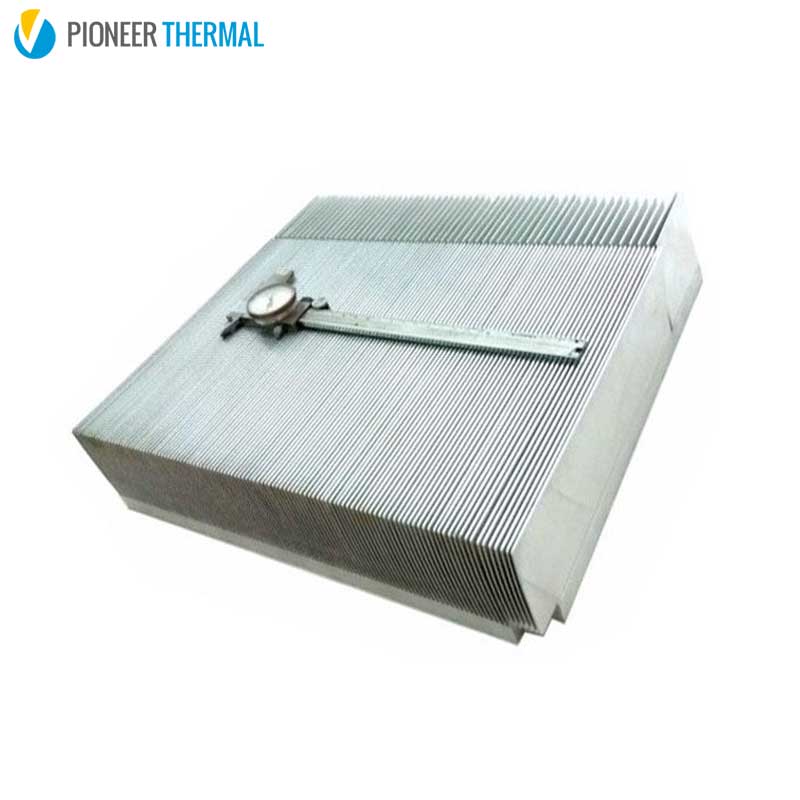

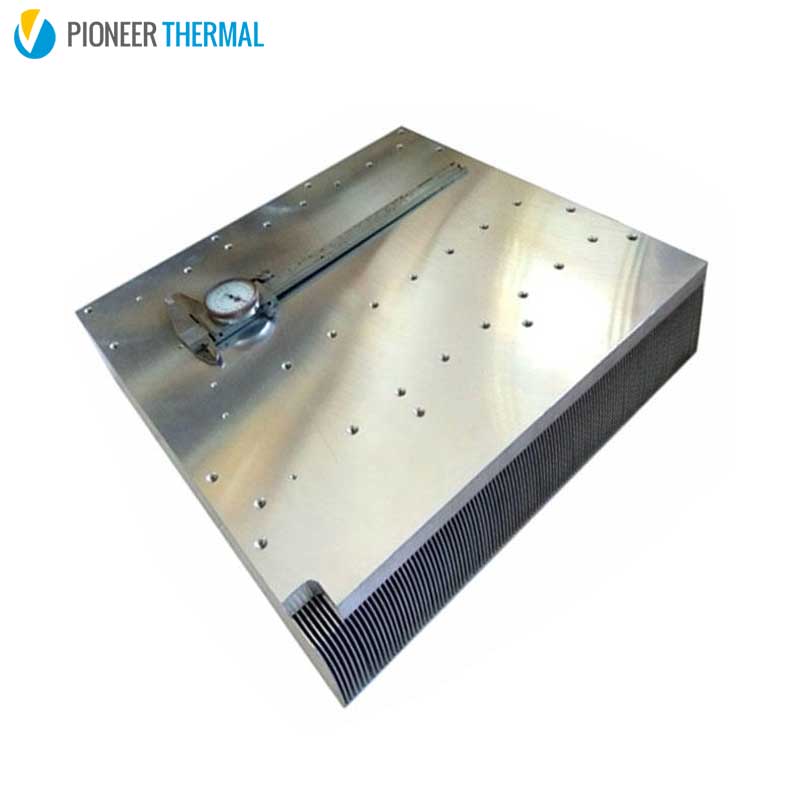

Skiving Heatsink Introduction

Skiving heatsink design:

1. Skiving heatsink Airflow lengths limited by cutter, maximum heat dissipation under forced convection (with high airflow)

2. Skiving heatsink can be designed very thin fins and very high with high density

3. Skiving heatsink material can be Aluminum and Copper.

4. Aluminum skiving heatsink with high aspect ratios( up to 50)

5.Skiving heat sink without filler material.

Technical Parameters

| Place of Origin: | Dongguan, China (Mainland) | OEM: | Yes |

| Process: | Skiving fin | Temper: | T3-T8 |

| Material: | Aluminum | Shape: | Square |

| Packing: | Paper carton, EPE, wooden pallet | Brand Name: | PIONNER THERMAL |

| Application: | Power System | Certificate: | ISO 9001:2015,ISO 14001:2015 |

| Model Number: | PT049 | Tolerance: | 0.05 mm |

| Finish: | Silver anodizing | Fin thickness: | 0.25 --2 mm |

| Extra process: | CNC Machining | Size: | 350x320x70mm |

|

AL1060 / AL 6063/ CU1100 Process parameter: |

|||

Video

Our Customers

Most of our heat sink are customized and widely applied in new energy, automotive, converter, PV inverter, IPC, server, telecom & communications infrastructure &power, LED lighting,medical equipment and other products.

+86-18902844286

+86-18902844286

E-mail

E-mail