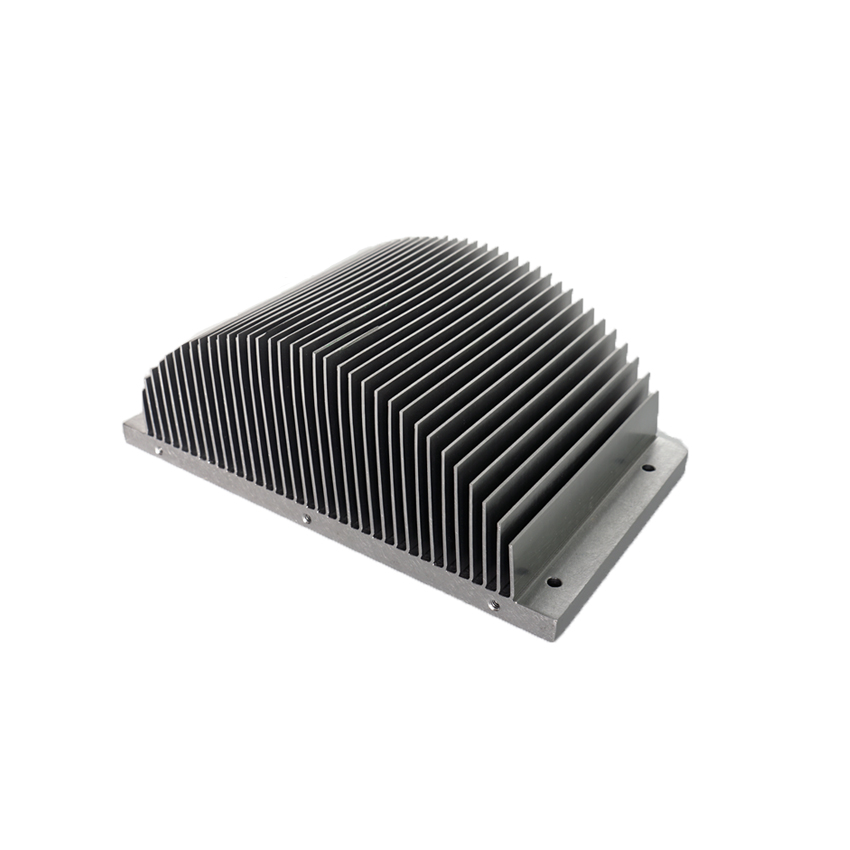

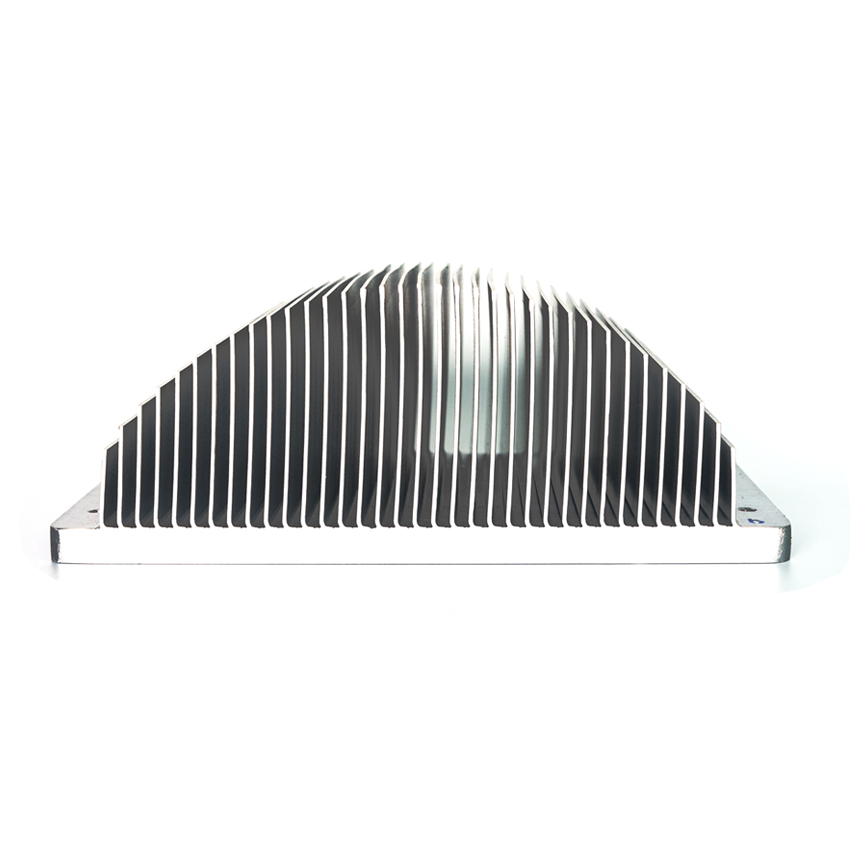

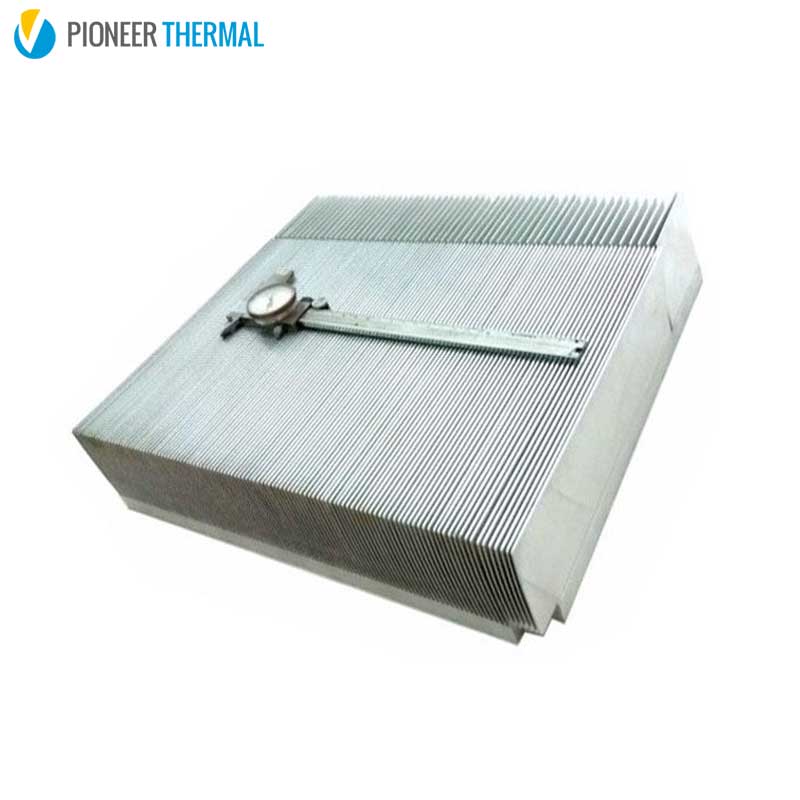

Product Introduction

The skiving fin process results in optimal thermal performance with high fin density and thin finned heat sink geometry. By packing as much fin surface area as possible into a given volume, a skived fin heat sink has greater heat transfer capability than other heat sinks with a single fin construction, such as extruded aluminum heat sinks. Compared to extruded aluminum, the manufacture of a skived fin does not need expensive tooling, providing greater design flexibility and faster prototyping. Instead, each fin is cut individually with the same tool, which reduces tooling costs.

Advantage of Skived Fin Heat Sinks

· High aspect ratio

· Thin fin

· Low tooling cost

· Easy and inexpensive to prototype

· Ideal thermal connectivity with the heat sink base

· Unidirectional flow

· Single piece construction

Skived fin heat sinks are commonly found in the following applications:

Computers and electronic components

Telecommunication equipment

Industrial equipment and components

Lighting lamps and household appliances industry

Automotive components

Skived fin heat sink process video:

+86-18902844286

+86-18902844286

E-mail

E-mail