From the manufacturing process point of view, a heat sink can be divided into below 11 types.

|

Heat Sink Types |

Material |

Tooling required |

MOQ |

Production Capacity/Month |

|

Extrusion heat sink |

AL6063-T5/T6 AL6061-T6 |

Yes |

>500pcs, suitable for medium and high volume order |

5,000,000 |

|

Stamping heat sink |

Stamping fin: AL1050, AL1100, AL3003, CU1100 Stamping plate: AL6061, AL6063 |

Yes |

>500pcs, suitable for medium and high volume order |

1,000,000 |

|

CNC machined heat sink |

AL5083, AL6060, AL6061, AL6063, AL6082, CU1100, CU1020 |

No |

Small volume to high volume |

200,000 |

|

Forged heat sink / pin fin heat sink |

AL1070, AL6063, CU1100 |

Yes |

>500pcs, suitable for medium and high volume order |

500,000 |

|

Die cast heat sink |

ADC12/ADC10/A380/A356 |

Yes |

>1000pcs, suitable for medium and high volume order |

1,000,000 |

|

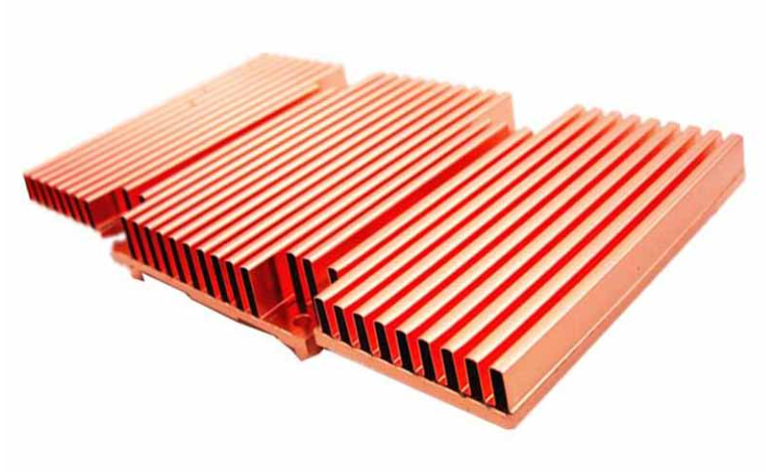

Skived fin heat sink |

AL1060/AL6063/CU1100 |

No |

Small volume to high volume |

500,000 |

|

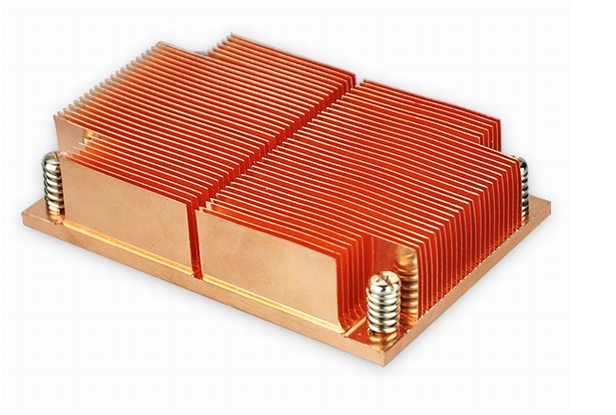

Soldering heat sink |

AL6063/AL6061/AL1100/CU1100 + copper C1020 |

Depends |

Small volume to high volume |

1,000,000 |

|

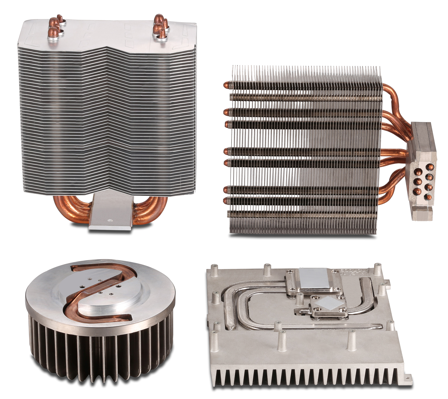

Heat pipe heat sink |

AL6063/AL6061/AL1100/CU1100 + copper C1020 |

Depends |

Small volume to high volume |

500,000 |

|

Vacuum Brazing heat sink |

AL6061, AL6063, AL3003 |

No |

Small volume to high volume |

100,000 |

|

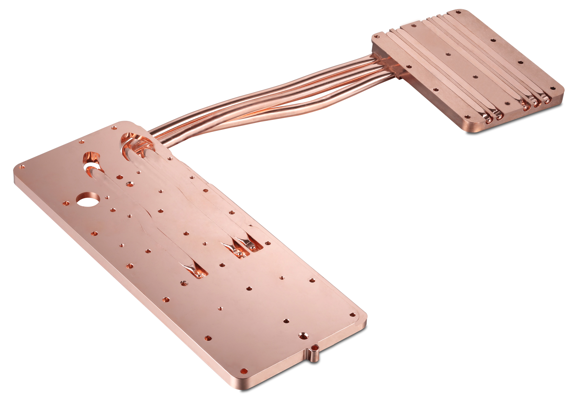

Vapor chamber |

CU1020 |

Yes |

Small volume to high volume |

100,000 |

|

Different types of cooling plate |

AL6082, AL6063, AL6061, AL3003 |

Depends |

Small volume to high volume |

100,000 |

1. Extrusion Heat Sink

Extrusion aluminum profiles are usually used to make LED heat sinks (usually the sun flower shaped heatsink), the material is mostly A6063. The advantages are:

a. The product heat dissipation effect is relatively good

b. The surface treatment of the finished product such as anodic oxidation is relatively easy.

c. Tooling production cycle is short, usually taking 10~15 days.

Some extrusion heat sink we made

2. Stamping Heat Sink

Stamping heat sink is made of stamped fin from a metal sheet by stamping tooling, then fins are soldered to base. Because the fin is stamped by an automatic machine, capacity is very high, hence the price is lower. But the performance is also relatively lower.

Some stamping heat sink we made

3. CNC machined heat sink

CNC machined heat sinks have more flexibility, they can achieve more complex shape and tighter tolerance, and also have much more material choice than other heat sinks. But when you have a large volume, CNC machining is not a cost-saving option for you.

Some CNC machined heat sink we made

4. Forging heat sink, also known as pin fin heat sink

Forging heat sink principle: forging is use of a forging machine to apply pressure to the metal billet through the tooling, so that the material produces plastic deformation, changing its original size, shape and performance, so as to obtain the desired shape and size of the forming processing method.

Forged heat sink process: Blank material --> softening (phosphating) --> forging --> machining --> surface treatment

Advantages of forging heat sink:

Forging can achieve less cutting or cutting-free processing, can save the cost of raw materials, high production efficiency, high strength, high precision, high surface finish, not only can replace the traditional die cast heat sink and extrusion heat sink, but cost performance is also better. With its unique characteristics, forging can also make complex shapes that other processes can not make, to meet the special performance requirements of some products. Product applicability is stronger.

5. Die cast heat sink

Die casting is a highly efficient manufacturing process that can produce parts with complex shapes. With die casting, heat sink fins can be incorporated into a frame, housing or enclosure, so heat can be transferred directly from the source to the environment without additional resistance. When used to its full potential, die casting provides not only excellent thermal performance, but also significant savings in cost.

High pressure die cast heat sinks are a cost effective alternative for high volume applications and allows us to produce complex shapes with a high degree of precision and repeatability. Our experienced design and manufacturing team can help you custom design a die cast heat sink optimized for your application to maximize heat transfer and cost effectiveness while minimizing weight and ensuring you optimize your die cast tooling investment.

Some die cast heat sink we made

6. Skived Fin Heat Sink

Skived fins are produced by a tool that shaves fins up from an aluminum or copper base, then standing the fins up, the fin-to-gap aspect ratio is extremely high, you can find the process video. Since it does not need soldering, the heat dissipation can reach the highest value.

Some skived fin heat sinks we made

7. Soldering heat sink

Welded heat sinks are heat dissipation products that are produced by using the soldering process as the main process.

From the base plate and fins from the welded heatsink, and combined with the two most commonly used materials of copper and aluminum, soldering heat sink can be divided into the following four categories according to the way they are welded together.

1. Aluminum fins + aluminum base plate welded together can form an all-aluminum soldering heat sink. The all-aluminum welded heat sink has several features:

a. high density of the fin;

b. light weight of the heat sink.

Because the heat dissipation effect of a heat sink under certain conditions is proportional to the heat dissipation area, the larger the heat dissipation area, the better the heat dissipation effect. Therefore, the density of the fin has increased, thus increasing the heat dissipation area, so its heat dissipation effect has been improved.

2. A copper base plate + copper fins welded together can form a pure copper heat sink. Copper's thermal conductivity K value is more than double that of aluminum, so its heat transfer performance will be better. In the heat dissipation problems that are difficult to solve with aluminum, you can choose to use copper to solve. However, pure copper heat sink will have some disadvantages, such as copper hardness is relatively low, the weight of copper is relatively heavy, the density is more than double that of aluminum, the price is also more than double that of aluminum.

3. Aluminum fins + copper base plate can be welded into a copper base plate aluminum fin soldering heat sink, the characteristics of this type of heat sink is to take into account the good heat transfer and uniform temperature performance of copper and light weight, low cost and better strength of aluminum

4. With an aluminum base plate + copper fins, this solves the problem of finer processing, and the finished heat sink has a relatively higher structural strength.

Some soldering heat sink we made

8. Heat pipe heat sink

Heat pipe heat sink is a kind of high-efficiency heat sink, which has unique heat dissipation characteristics. That is, it has high thermal conductivity, and the distribution of temperature along the axial direction between its evaporation section and cooling section is uniform and basically equal.

The thermal resistance of the heat sink is determined by the thermal conductivity of the material and the effective area within the volume. When solid aluminum or copper heat sinks in the volume of 0.006m³, increasing its volume and area can not significantly reduce the thermal resistance. For two-sided heat discrete semiconductor devices, air-cooled all-copper or all-aluminum heat sink thermal resistance can only reach 0.04 ℃ / W. And heat pipe heat sink can reach 0.01 ℃ / W. In natural convection cooling conditions, heat pipe heat sink performance can be increased by more than ten times compare to physical heat sink.

Heat pipe heat sinks have the following advantages.

1. Fast thermal response, its ability to transfer heat is more than 1000 times greater than that of copper tubes of the same size and weight;

2. Small size and lightweight;

3. High heat dissipation efficiency, which can simplify the design of heat dissipation of electronic equipment, such as changing air cooling to self-cooling;

4. No external power supply is required, and no special maintenance is needed when working;

5. Has very good isothermal, after thermal equilibrium, the temperature gradient between the evaporation section and the cooling section is quite small, which can be approximated as 0;

6. The operation is safe and reliable and does not pollute the environment.

Some heatpipe heatsink we made

9. Vacuum brazing heat sink

Vacuum brazing is a relatively new brazing method developed to meet the needs of the aerospace, marine development, atomic energy, electronics and chemical industry. The vacuum brazing process does not require a brazing flux to join highly reactive metals such as aluminum and titanium, and at the same time ensures a precise and bright joint with excellent mechanical properties and corrosion resistance. Vacuum brazing is carried out in a vacuum furnace, and with the continuous improvement of the vacuum furnace performance to price ratio, aluminum vacuum brazing furnace has been used in a large number of civilian and military industries. Aluminum vacuum brazing has obvious advantages compared to salt bath brazing and flux brazing:

1. Non-toxic and non-polluting;

2. No brazing flux, no slag, no post-weld cleaning, saving labor and material resources;

3. Heating in a vacuum, no oxidation problems, and very large workpieces can be processed;

4. Uniform heating and small deformation can be achieved without trimming after welding, which is very necessary for high-precision aluminum waveguides that are difficult to clean and trim after welding, and also more suitable for brazing of air-cooled heat sinks and water-cooled cold plates.

The vacuum furnace consists of a vacuum chamber, a heater, a control system and a supporting vacuum system. Nowadays, the mainstream aluminum vacuum brazing is a cold-wall furnace with water-cooled walls, which provides good production conditions and high quality of brazed workpieces and is suitable for processing of small-lot and multi-species parts.

Some Vacuum brazing heat sink we made

10. Vapor chamber heat sink

Vapor Chamber Heatsink is constructed from sealed copper plates and filled with a small amount of fluid such as deionized water that allows heat to be rapidly dispersed away from the source. Inside the chamber resides an internal support structure to prevent the buckling of chamber walls. Classified formally as a heatpipe, a vapor chamber is one of the best heat spreading options at the base of a heatsink; and typically used for high power devices. When combined with stamped fins, it creates a high-end thermal management device that can rapidly spread heat from a small source to a large surface area.

A Vapor Chamber Heatsink can be integrated with either aluminum or copper heatsinks. The simplest method is to solder a vapor chamber to the base of an extruded heatsink. A more thermally efficient method is to solder a stack of stamped fins directly to the surface of a vapor chamber. To improve the dimensional integrity, these fins are often interconnected by locking tabs called zipper fins.

Some Vapor chamber heat sink we made

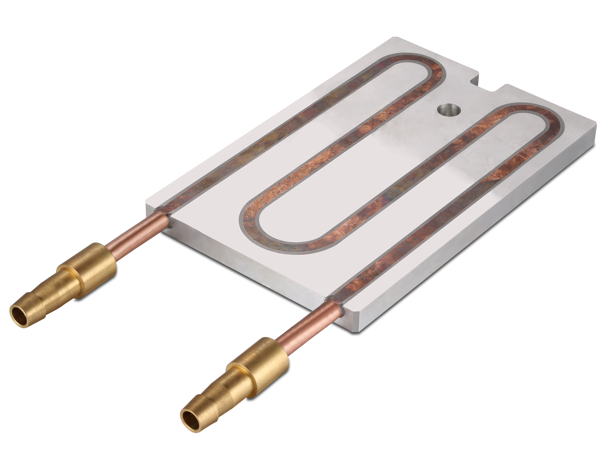

11. Cooling plate

When natural cooling and air cooling are unable to meet the heat dissipation requirement, water-cooled cooling has become the direction of choice, the original water-cooled cooling plates are more expensive, the process is also more complex, so the use of water-cooled cold plate range is not very wide. However, with the development of technology, especially the maturity of the cooling manufacturing process, the cost of water-cooled cold plates have reduced. In addition, as the product design becomes more sophisticated, water cooling cold plates undoubtedly has unparalleled advantages over other cooling methods in terms of thermal performance, and is therefore valued by thermal design engineers.

Friction Stir Welding Cold Plate

Friction stir welding process is commonly used in the thermal design and production of water-cooled cold plates. The process is to open a slot on the aluminum base, that is, the water channel slot, and then put a thin aluminum plate on the base, and then use the friction stir welding process to weld the thin aluminum plate to the base, the water channel required for heat dissipation is done. Or machining the base into a micro-channel water channel, and then laying a piece of aluminum plate on the base, sealed the micro channel by friction stir welding. You can refer to the video on this page.

Friction welded heat sinks have the same shape as profile heat sinks, but with larger dimensions and higher cooling power.

Friction stir welding cold plate has the following advantages:

1. Realizes the production of high-fold ultra-wide body and large size heat sink structure, solving the technical bottleneck of profile heat sink;

2. Friction stir welding is a non-medium thermal fusion, which is equivalent to the extrusion heat sink to be extruded at one time and achieves 100% thermal conductivity of material;

3. Lower development cost;

4. Shorter development cycle;

5. High stability of friction stir welding cooling plate and easy maintenance.The water cooling plate made by the friction stir welding process is lower cost but more reliable.

Friction stir welding has been used in aviation, aerospace, nuclear energy, weapons, automotive, electric power, marine development, machinery manufacturing etc. other new technologies and traditional industrial sectors with its high quality, high efficiency, energy saving, non-polluting technical characteristics.

If you do not know which type of heat sink suits your needs the best, contact us now, our professional will give you the best solution based on your application.

+86-18902844286

+86-18902844286

E-mail

E-mail