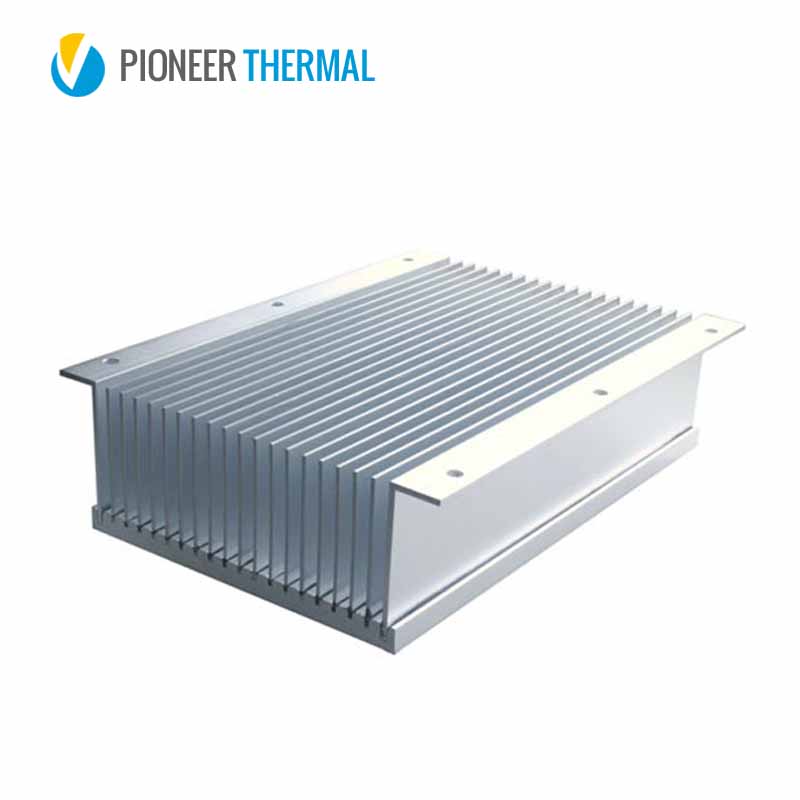

Product Introduction

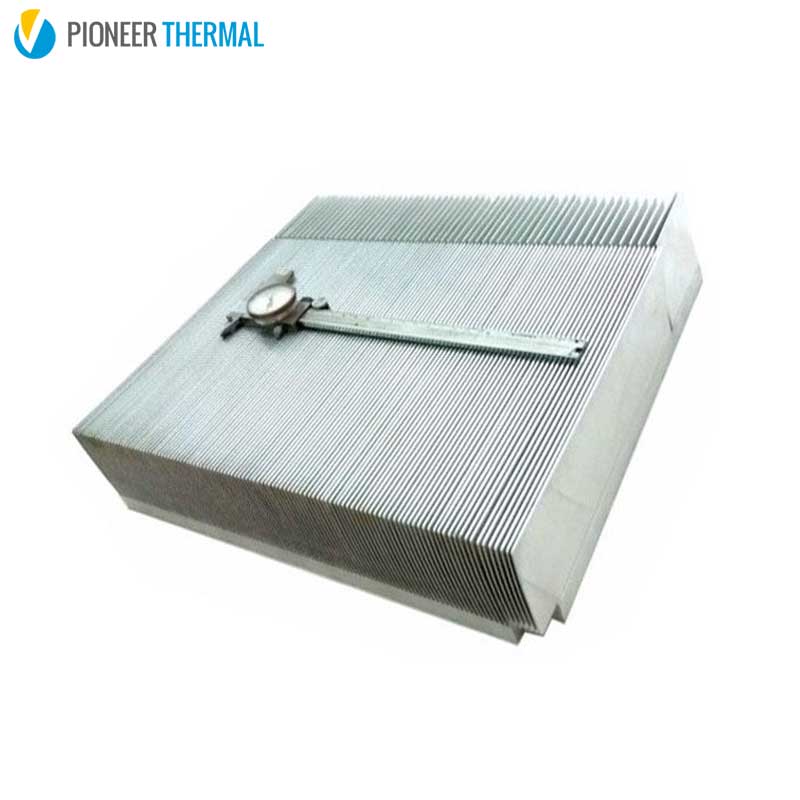

Brazed fin heat sinks are an assembly of a grooved base with individual fins bonded into the grooves. This type of heat sink fabrication allows for higher fin densities and fin aspect ratios than what is manufacturable with extrusion methodologies, greatly improving thermal performance as compared to extruded heat sinks due to increased surface area.

Pioneer's broad portfolio of standard extruded bases and standard cut aluminum fins allows us to quickly design and manufacture semi-custom epoxy bonded fin solutions as well as fully custom heat sinks and systems featuring bonded or brazed fin types.

Specifications of Brazed Fin Heat Sink

| Place of Origin: | Dongguan, Guangdong China (Mainland) |

| Process: | Brazed, CNC machining |

| Temper: | T3-T8 |

| Material: | Aluminum、Copper、Stainless Steel |

| Shape: | Customize |

| Fin thickness | typically ranges from .010” to .080” (other thicknesses as needed) |

| Brand: | Pioneer Thermal |

| Application: | Optical communication equipment |

| Certificate: | ISO 9001:2015,ISO 14001:2015, TS16949 |

| Tolerance: | 0.01 mm |

| Fins: | Fins can easily be non-uniform geometry, especially length, with no post machining |

| Extra process: | CNC Machining |

| Quality control: | 100% quality checking |

| Size: | custom design |

| Sample Service: | Different sizes are available for prototypes test |

Heatsink R&d Advantages

As a heat sink manufacturer, Pioneer Thermal can customize Brazed Fin Heat Sink, more important, we have our own R&D team

who can design heat sink and run simulation to find the best and cost reasonable solution for your application.

+86-18902844286

+86-18902844286

E-mail

E-mail