Product Introduction

Manufacturing process:

1. Aluminum fin: by stamping process with progressive die

2. Aluminum base: by extrusion process

3. Bracket: by stamping process

4. Heat pipe forming: by heat pipe bending machine

5. Assemble aluminum fin, aluminum base and heat pipe by soldering process with reflow oven.

6. Assemble bracket and screws

7. Apply thermal degrease with screen fixture

8. 100% on-line thermal test

9. Pack and ship.

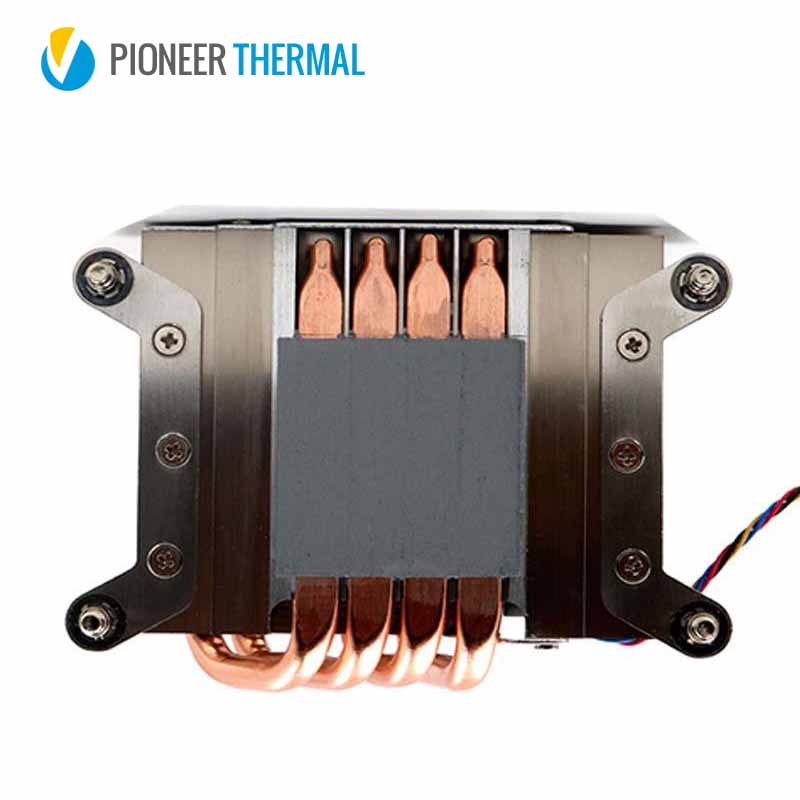

Specifications of Copper Heat Pipe Heat Sink

| Place of Origin: | Dongguan, Guangdong China (Mainland) |

| Process: | Soldering |

| Temper: | T3-T8 |

| Material: | Heat pipe+ AL |

| Shape: | Customized |

| Heat-dissipating mehthod: | Passive cooling |

| Brand: | Pioneer Thermal |

| Application: | Intel LGA2011 Narrow Fan speed |

| Certificate: | ISO 9001:2015,ISO 14001:2015, TS16949 |

| Input voltage : | DC 12V |

| Finish: | Nickel plated + anti-oxidation |

| Extra process: | Stamping |

| Quality control: | 100% thermal test |

| Size: | Custom size |

As a heat sink manufacturer in China, Pioneer Thermal is certified with ISO9001, ISO14001 and TS16949, and has more than 18 years experience in CNC machining, cold forging heatsinks, cold plate heatsinks, die casting heatsinks, extrusion heatsinks, heatpipe assemblies, skived fin heatsinks, stacked fin heatsinks, folded fin heatsinks etc., Pioneer Thermal has own R&D team who can design and run simulation for you if you require design service, or assist your design team to improve the part feasibility from the manufacture point of view (design refine/process optimize/cost reasonable). If you need any heat sink service, please contact Pioneer Thermal.

+86-18902844286

+86-18902844286

E-mail

E-mail