Product Introduction

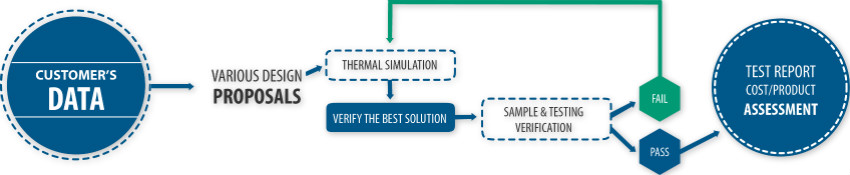

Our experienced thermal design team can provide custom heatpipe design assistance for telecommunication, test equipment, IT industry, medical equipment and power supplies. We provide design for thermal management in the early stage of product development based on the customer requirements. Using thermal simulation software we provide a cost effective solution.

Manufacturing Process

Heat pipe is placed inside the die casting tooling, and the molten aluminum water wraps the heat pipe during die casting process.

Aluminum extrusion part on the back side is epoxied to the die cast part.

CNC machining threads and holes.

Workshop

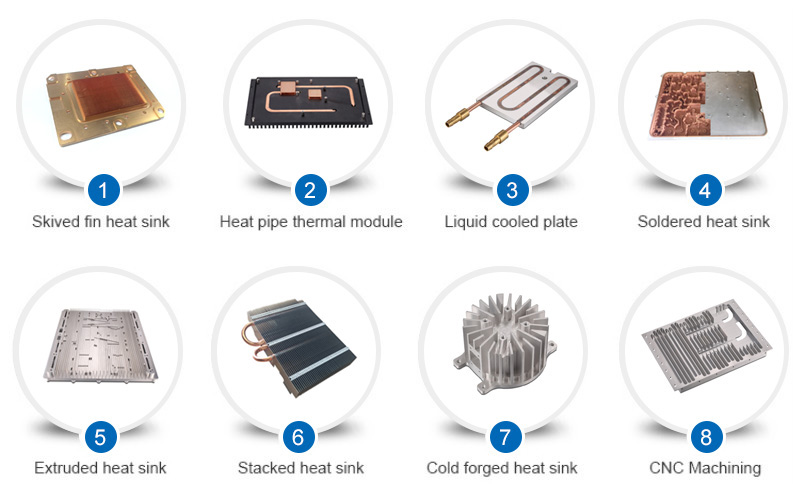

As a heat sink manufacturer in China, Pioneer Thermal is certified with ISO9001, ISO14001 and TS16949, and has more than 18 years experience in CNC machining, cold forging heatsinks, cold plate heatsinks, die casting heatsinks, extrusion heatsinks, heatpipe assemblies, skived fin heatsinks, stacked fin heatsinks, folded fin heatsinks etc., Pioneer Thermal has own R&D team who can design and run simulation for you if you require design service, or assist your design team to improve the part feasibility from the manufacture point of view (design refine/process optimize/cost reasonable). If you need any heat sink service, please contact Pioneer Thermal.

Design Flowchart

Our Customers

+86-18902844286

+86-18902844286

E-mail

E-mail