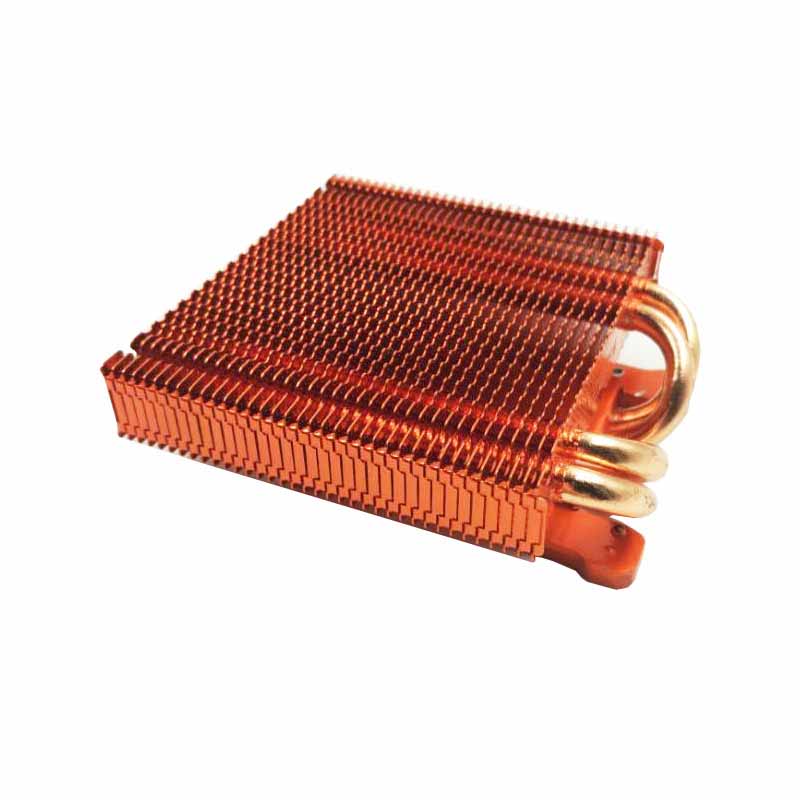

Heat Pipe Welding Heat Sink

Pioneer Thermal heat pipe heat sink has the following advantages:

1. The thermal response speed is fast, and its ability to transfer heat is more than 1000 times larger than that of copper pipes of the same size and weight;

2. Small size and light weight;

3. High heat dissipation efficiency, which can simplify the heat dissipation design of electronic equipment, such as changing air-cooling to self-cooling;

4. No external power supply is required, and no special maintenance is required during work;

5. It has good isothermal properties.

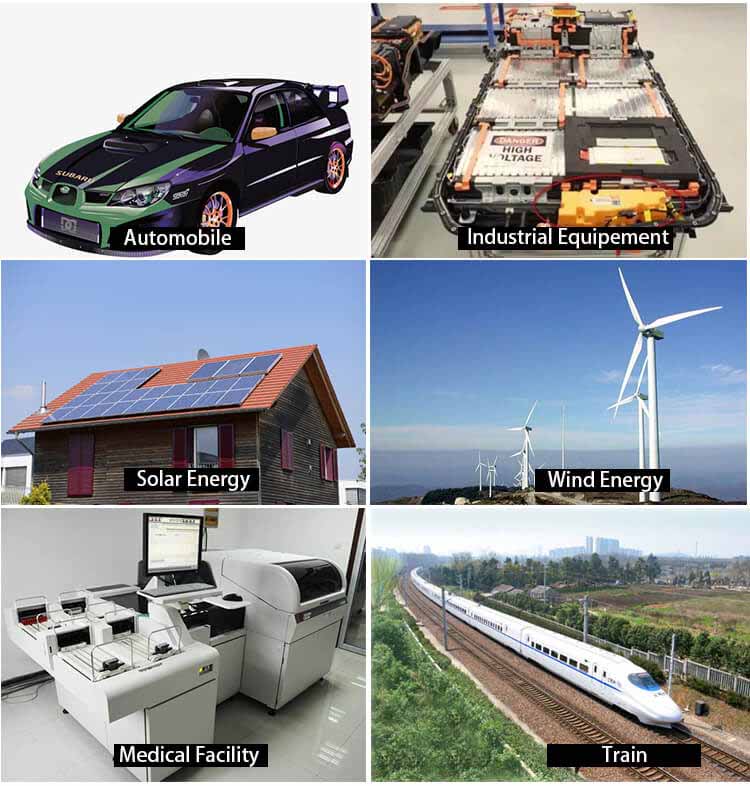

Heat pipe heat sink is a new product produced by using heat pipe technology to make major improvements to many old radiators or heat exchange products and systems. There are two types of heat pipe heat sinks: natural cooling and forced air cooling. The thermal resistance of air-cooled heat pipe radiators can be made smaller, and they are often used in power electronics, IGBTs, inverters, transformers, high-power power supplies, LED lamps, servers, computers, medical beauty products, etc.

+86-18902844286

+86-18902844286

E-mail

E-mail