Product Introduction

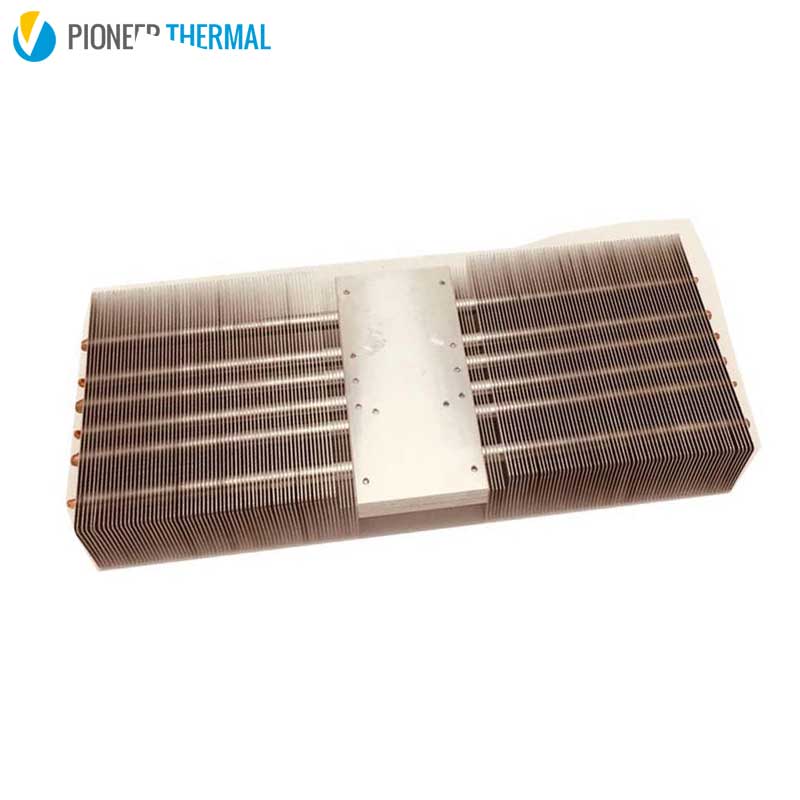

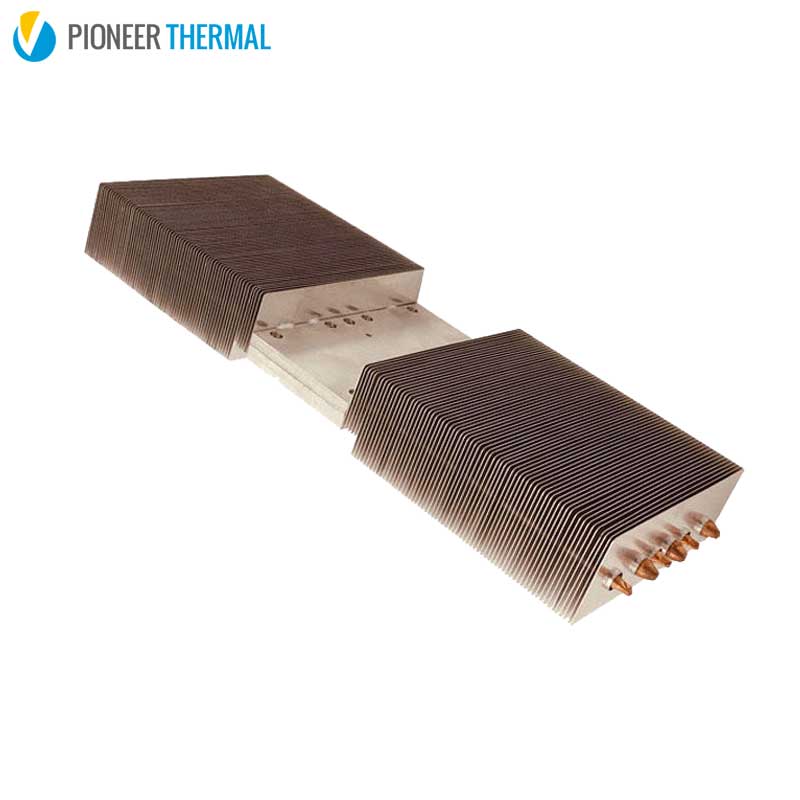

Heatpipe Heatsink manufacturing process:

Aluminum fin: Progressive die stamping fin process

Aluminum base plate : CNC machining process

Heat pipe forming: automatic heatpipe bending

Aluminum base plate and aluminum fin nickel plated, heatpipe anti-oxidation (insulation, oxidation and corrosion resistance)

Assembly: aluminum fin, aluminum base and heatpipe assembled by soldering process through our reflow oven

Quality: 100% on-line thermal test, CMM, caliper.

Parameters

| Place of Origin: | Dongguan, China (Mainland) | OEM: | Yes |

| Process: | Soldering | Temper: | T3-T8 |

| Material: | Copper Pipe +Aluminum zipper fin + aluminum base | Shape: | Customize |

| Packing: | Carton with plywood pallet | Brand Name: | PIONEER THERMAL |

| Application: | Projector | Certificate: | ISO 9001:2015,ISO 14001:2015, TS16949 |

| Model Number: | PT036 | Tolerance: | 0.01 mm |

| Finish: | Chemical nickel plating | Quality control: | 100% on-line thermal test |

| Extra process: | Stamping+CNC Machining | Size: | Custom size |

| Applied Field: | Aerospace, cpu, Solar energy,led, new energy automotive, PV inverter | ||

Workshop

As a heat sink manufacturer in China, Pioneer Thermal is certified with ISO9001, ISO14001 and TS16949, and has more than 18 years experience in CNC machining, cold forging heatsinks, cold plate heatsinks, die casting heatsinks, extrusion heatsinks, heatpipe assemblies, skived fin heatsinks, stacked fin heatsinks, folded fin heatsinks etc., Pioneer Thermal has own R&D team who can design and run simulation for you if you require design service, or assist your design team to improve the part feasibility from the manufacture point of view (design refine/process optimize/cost reasonable). If you need any heat sink service, please contact Pioneer Thermal.

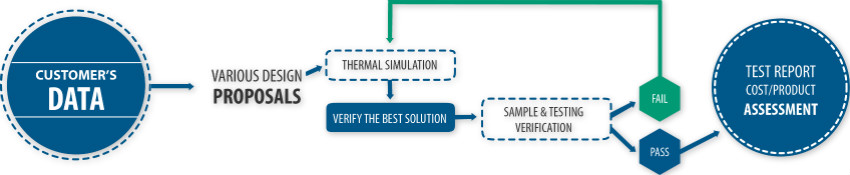

Design Flowchart

+86-18902844286

+86-18902844286

E-mail

E-mail