Product Introduction

Copper Skived fin heatsinks advantages

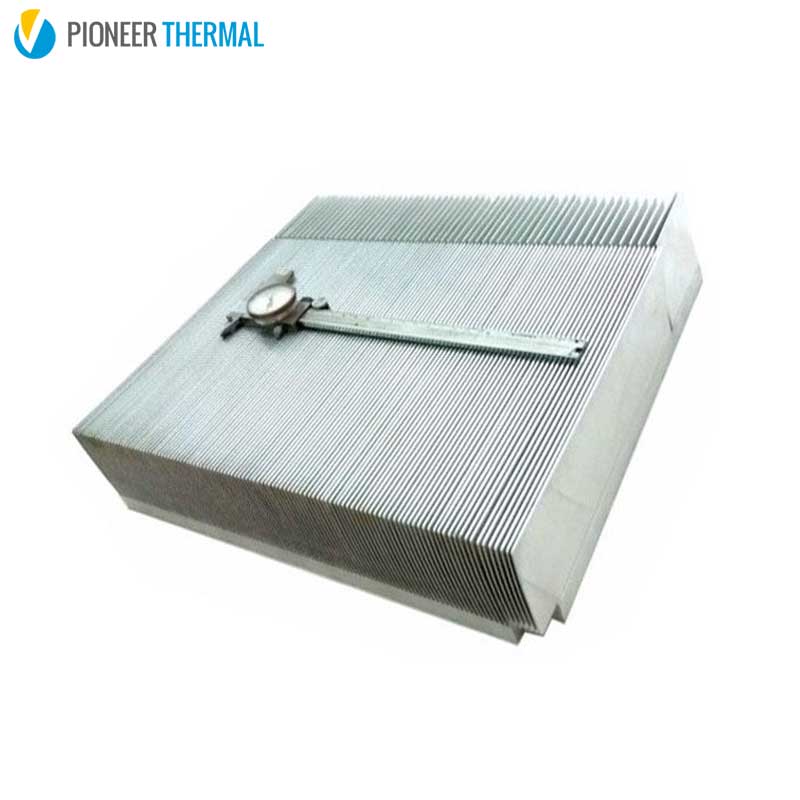

Skived fin heatsinks can be an alternative to extruded heat sinks, because the high density fin,high performance, high aspect ratio, excellent performance heat sink can’t be achieved by extrusion technology.

Skived fin heatsinks fabrication does not need expensive mold which provides greater design flexibility. Instead, each fin is cut separately using the same tool which allows for lower tooling costs.

Besides,this skived fin heatsinks are made of copper and with ultrathin fins, copper with high thermal conductivity than aluminum and the skiving process is a good thermal solution for high power device cooling.

Copper skived fin heatsinks widely used for computer, Power Transistor, PV inverter, converter, new energy, FET, IC, Power Amplifier, Voltage Regulator, Server, SCR etc.

Manufacturing Process

Skived fin heatsinks: When passing through the machine, slabs are skived in a specific angle so as to form and bend the fins. With the repetitive cutting, it forms consistent gaps and structures and can be used for cooling high-power devices under air-cooled conditions. This process can enhance 8~15% of the cooling capacity as compared to the stitched fin process.

Skived Heatsinks Copper Technical Parameters

| Place of Origin: | Dongguan, China (Mainland) | OEM: | Yes |

| Process: | Skived fin | Temper: | T3-T8 |

| Material: | Copper | Shape: | Customized |

| Packing: | Paper carton with plywood pallet | Brand Name: | PIONNER THERMAL (PT) |

| Application: | Server, projector, camera, inverter, converter etc. | Certificate: | ISO 9001:2015,ISO 14001:2015, TS16949 |

| Model Number: | PT048 | Tolerance: | 0.05 mm |

| Finish: | Passivation | Fin thickness: | 0.25 --2 mm |

| Extra process: | CNC Machining | Size: | Customized |

|

AL1060 / AL 6063/ CU1100 Process parameter: |

|||

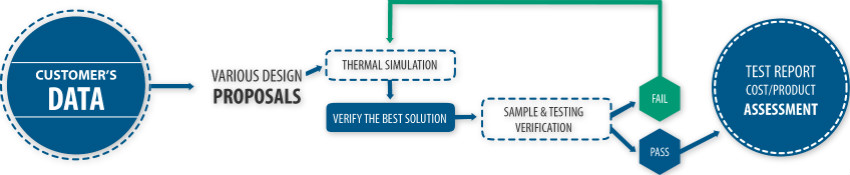

Design Flowchart

+86-18902844286

+86-18902844286

E-mail

E-mail