Product Introduction

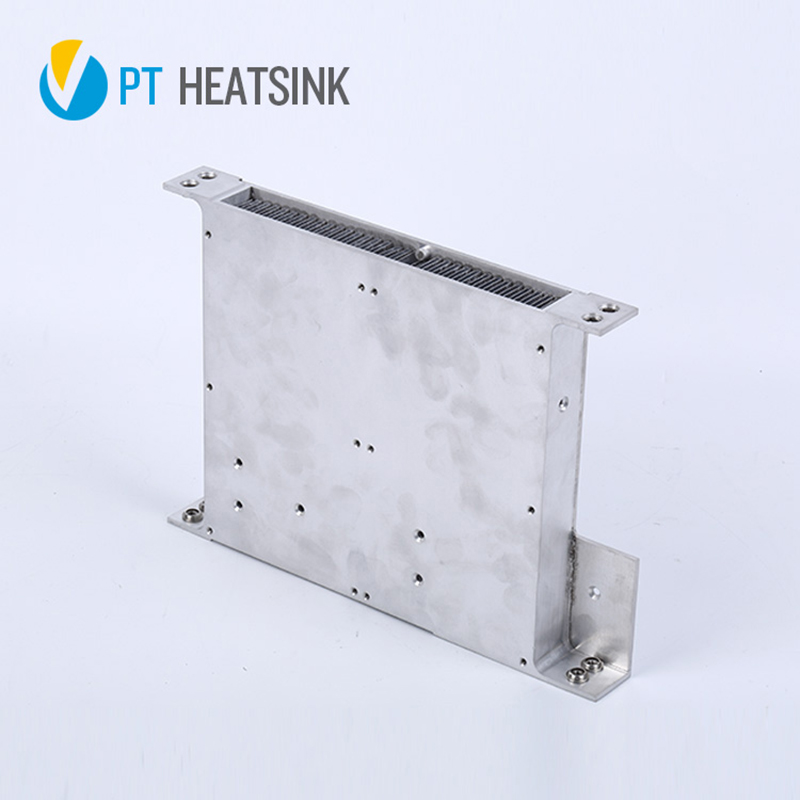

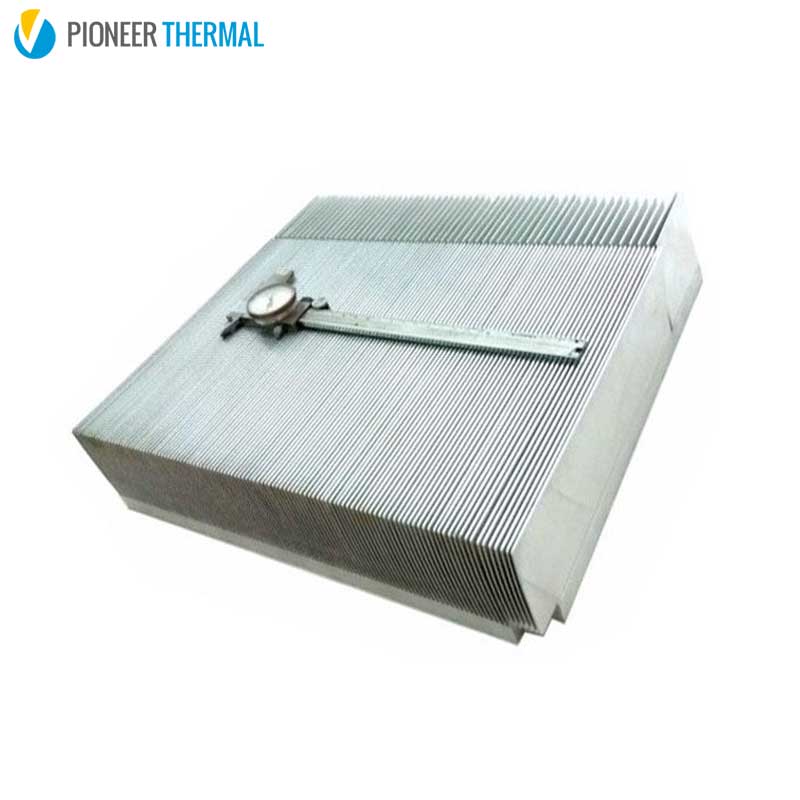

Folded fins are made from bending aluminum and copper sheets before bonding to a base. These fins can be much thinner than typical extruded or bonded fins, and provide higher densities and surface areas. The folded fins are then attached to the heatsink base by brazing, solder or epoxy resin. Folded fin heat sinks are available in either aluminium or copper.

Manufacturing Process

1. Folded fin

2. CNC machining aluminum plate

3. Braze folded fin and aluminum plate, this process is pretty complex, the fins are very thin and is not very easy to brazed well for each fin. Pioneer Thermal has made thousands of this folded fin heat sink, we have made many failure parts in the past, but with constantly improving, now we are very successful at making this folded fin heat sink. If you have any folded fin heat sink inquiry, Pioneer Thermal is definitely your choice.

4. Surface treatment

5. Inspect, pack and ship.

Our Workshop:

As a manufacturer of heat sink in China, Pioneer Thermal is certified with ISO9001, ISO14001 and TS16949, and has more than 18 years experience in CNC machining, cold forging heatsinks, cold plate heatsinks, die casting heatsinks, extrusion heatsinks, heatpipe assemblies, skived fin heatsinks, stacked fin heatsinks, folded fin heatsinks etc., Pioneer Thermal has own R&D team who can design and run simulation for you if you require design service, or assist your design team to improve the part feasibility from the manufacture point of view (design refine/process optimize/cost reasonable). If you need any heat sink service, please contact Pioneer Thermal.

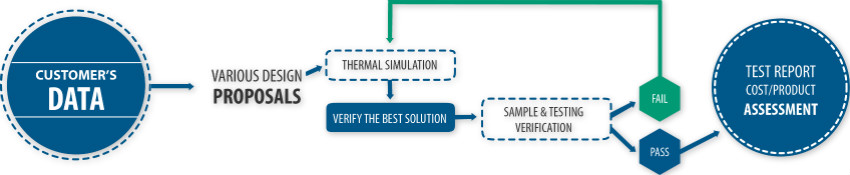

Design Flowchart

+86-18902844286

+86-18902844286

E-mail

E-mail