Skiving Heatsink With Heatpipe Introduction

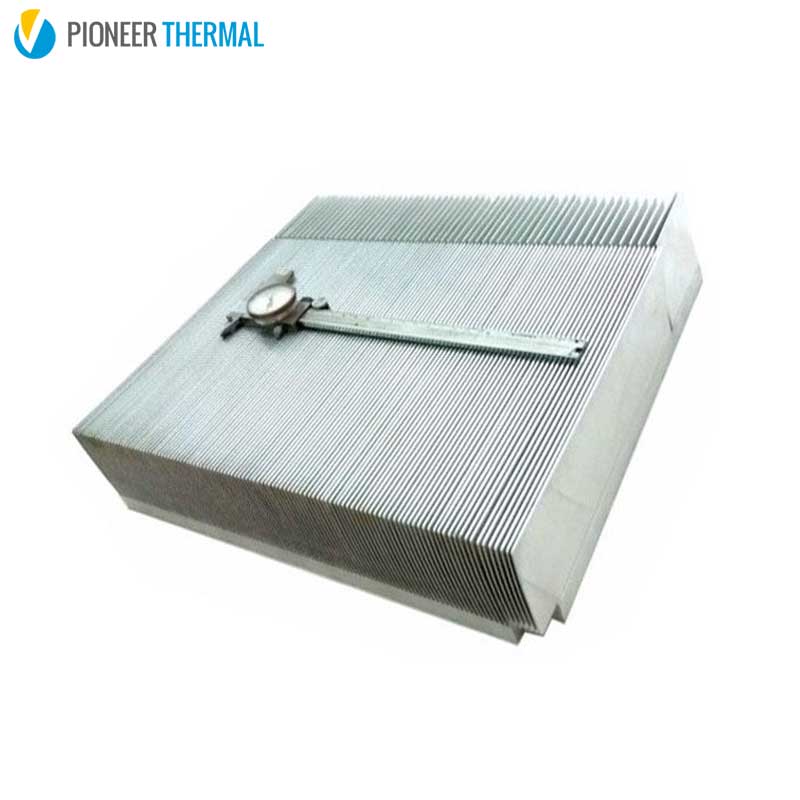

Skiving heat sink use special plates and special skiving equipment to chip the required chain links. With the ultra-small spacing, multiple and ultra-high heat sink body structure, the efficiency of the heat sink is twice of the traditional heat sink, and the material purity is high.

1. Skiving technology leading the heat innovation innovation high density ,high thermal performance, high aspect ratio, excellent performance.

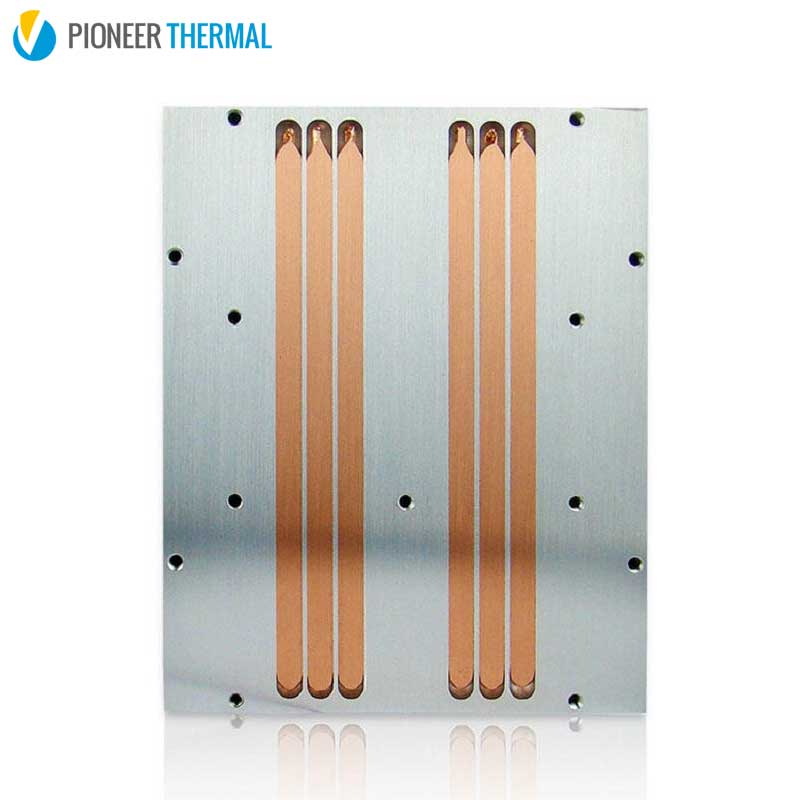

2. Skiving heatsink soldering with heatpipe, it owned both the advantage of Al Material and heat pipe

3. This skiving heatsink size is 200*159*59mm, we can manufacture vary size according to your needs.

Skiving Heatsink With Heatpipe Technical Parameters

| Place of Origin: | Dongguan, China (Mainland) | OEM: | Yes |

| Process: | Skiving+ soldering+ CNC Machining | Temper: | T3-T8 |

| Material: | AL6063 + Heat pipe CU1020 | Shape: | Rectangle |

| Packing: | Paper carton with plywood pallet | Brand Name: | PIONEER THERMAL (PT) |

| Application: | Cooling high-power devices | Certificate: | ISO 9001:2008,ISO 14001:2015, TS16949 |

| Model Number: | PT045 | Tolerance: | 0.05 mm |

| Finish: | nickel plated + anti-oxidation | Fin thickness: | 0.25 --2 mm |

| Design | Custom made | Size: | 200x159x59mm |

| Applied Field: | Telecommunication, UPS, inverters, controllers, wind power converters, and SVG | ||

|

Skiving heatsink Process parameter: Materials: Copper (C11000) or Aluminum (6063) Base thickness: 1~30 mm Fin length: <550 mm Fin height: <120 mm Recommended fin height: <50 mm Recommended fin thickness: 0.3-0.6 mm |

|||

Skiving Heatsink Production Video

Skiving heatsink: When passing through the machine, slabs are skived in a specific angle so as to form and bend the fins. With the repetitive cutting, it forms consistent gaps and structures and can be used for cooling high-power devices under air-cooled conditions. This process can enhance 8~15% of the cooling capacity as compared to the stitched fin process. Leading the heat innovation innovation high density ,high performance, high aspect ratio, excellent performance.

+86-18902844286

+86-18902844286

E-mail

E-mail