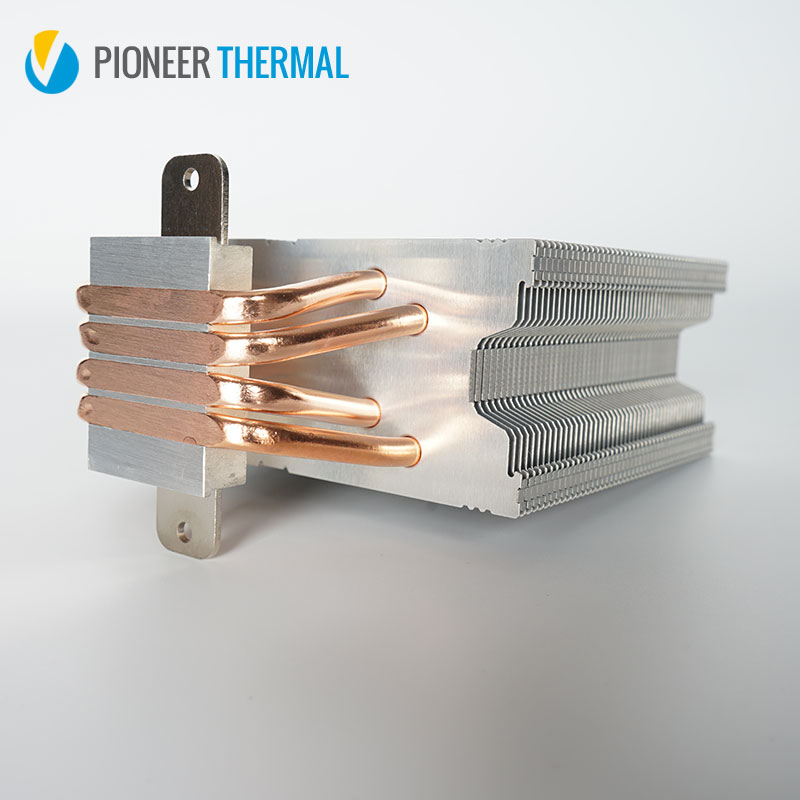

Stamped Fin Heat Sink For CPU Product Introduction:

From design to prototype to production, Pioneer Thermal is at your service. Pioneer Thermal Heatsink Technology was established in 2003 in Dongguan, China, with branch offices in the United States and Singapore. Our primary facility is equipped with industry-leading production machines covering CNC machining, extrusion, stamping, cold forging, die casting, skiving fin, heat pipe assembly, water cooling plate, friction stir welding, vapor chamber, heat sink assembly, and inspection through packaging.

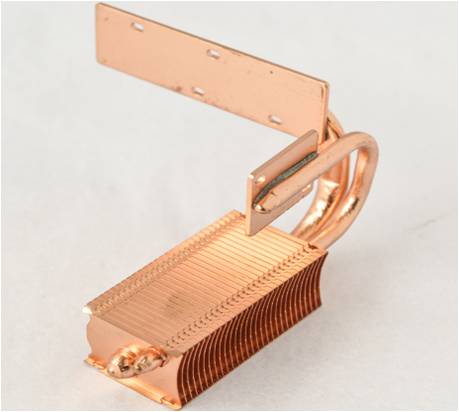

A custom stamped fin heat sink is made from sheets of aluminum or copper, where the metal is stamped into a particular configuration based on the intended application. For maximum design flexibility, fins can be stamped into a broad range of geometries and thicknesses. A stamped fin heat sink is a useful approach for medium to high volume production.

Stamping Heat Sink with Premier Quality

○ Multi-tonnage punching machines to meet the requirements of different types of products

○ High-speed punching machines with more than 300 strokes per minute can greatly increase productivity

○ Professional mold design and mold processing center make the products can be produced more quickly and accurately

Send Inquiry Now

○ Multi-tonnage punching machines to meet the requirements of different types of products

○ High-speed punching machines with more than 300 strokes per minute can greatly increase productivity

○ Professional mold design and mold processing center make the products can be produced more quickly and accurately

Send Inquiry Now

Stamped Fin Heat Sink Process:

Stamping process is a metal processing method, which is based on the plastic deformation of metal, using the die and stamping equipment to apply pressure to the plate material to produce plastic deformation or separation of the plate material, so as to obtain stamped fin with certain shape, size and performance.

1. CNC machining aluminum block

2. Fin is produced by stamping machine

3. Aluminum block and fin nickel plated

4. Heat pipe bend and flycut

5. Soldering stamp fin, heat pipe and aluminum block

6. On line thermal test

7. Surface treatment: degrease + heat pipe anti-oxidation

8. Pack and ship stamped fin heat sink

Pioneer Thermal heat sink have 16 years of experience in custom heat sinks, our focus has always been to provide superior customer service in the high quality cost-effective custom heat sink area. Any custom heatsinks and standard heatsinks demand, please contact us directly.

+86-18902844286

+86-18902844286

E-mail

E-mail