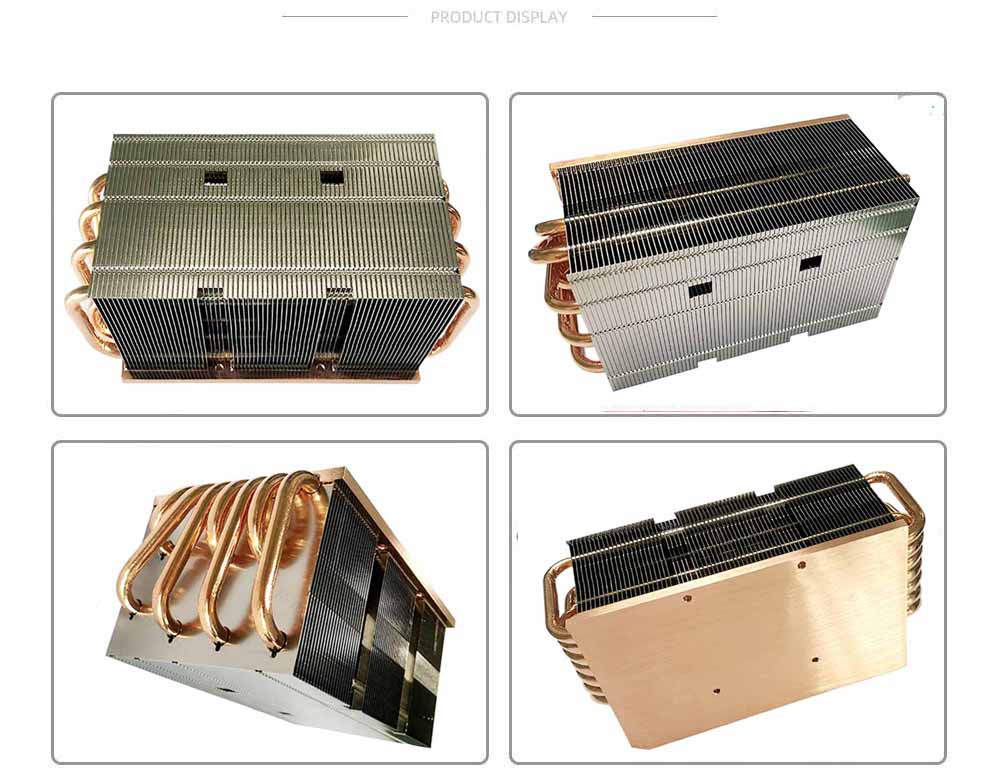

Stacked Fin Heat Sink Product information

| Material: | Aluminum stack fin+ copper heat pipe+ copper base | Process: | Stamping + Soldering + nickel plated |

| Tolerance: | 0.01 mm | Quality control: | 100% thermal test |

| Application: | Industrial Computer/Server/Processor etc. | Certificate: | ISO 9001:2008,ISO 14001:2004 |

| Packing: | Paper carton with plywood pallet | Brand Name: | PT |

| Place of Origin: | Dongguan, China (Mainland) | OEM: | Yes |

Stacked Fin Heat Sink Details

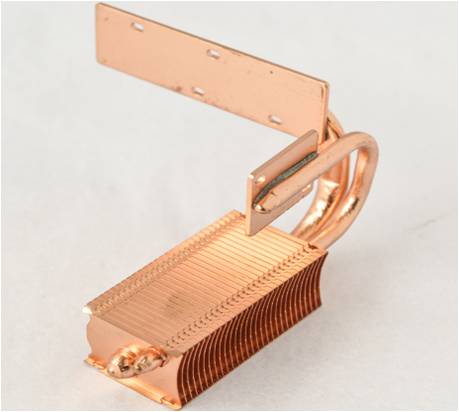

This stacked fin heat sinks is made by punching + soldering process, stacked fin heat sinks can increase cooling area, by soldering the heat pipe, it will achieve higher thermal performance.

The stacked fin heat sink is an ideal air cooling solution for high power forced convection applications in mass production. A stacked fin heat sink consists of a series of individual metal fins that are stamped, folded, and pulled together using interlocking features. The length and clearance of the fins can be varied by using different stamping dies, and the fins can be closed and stacked to create a finned duct, or opened for multi-directional airflow depending on the application airflow requirements.

A complete stack fins is typically welded, brazed or epoxied to a heat sink base or series of heat pipes to create a full thermal management assembly. Since stack fins are attached at both the top and bottom of the fin, they offer a higher degree of mechanical stability than other fin types, such as skived or folded fins.

Stack fins offer a high degree of design flexibility, which allows PT's engineers to design comprehensive solutions with heat pipes, ducts, and fans to meet customer application requirements.

+86-18902844286

+86-18902844286

E-mail

E-mail