Product Information:

| Place of Origin: | Dongguan, China (Mainland) | OEM: | Yes |

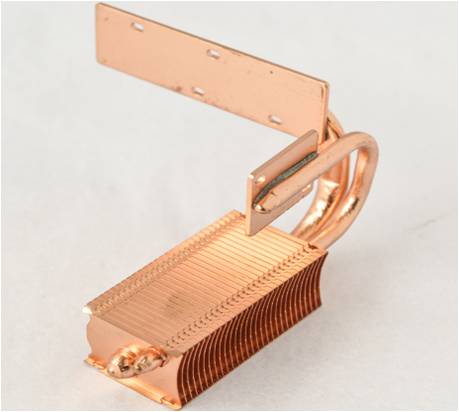

| Process: | Stamping + Soldering + nickel plated | Temper: | T3-T8 |

| Material: | Aluminum zipper fin+ heat pipe+Aluminum base | Shape: | Customized |

| Packing: | Paper carton with plywood pallet | Brand Name: | PT |

| Application: | Wind power converter, new energy, server | Certificate: | ISO 9001:2008,ISO 14001:2004 |

| Tolerance: | 0.01 mm | Quality control: | 100% thermal test |

Product Details

Heat pipe heat sink has the following advantages:

1. Fast thermal response, its ability to transfer heat is more than 1000 times greater than that of copper tubes of the same size and weight;

2. Small size and light weight;

3. High heat dissipation efficiency, which can simplify the design of heat dissipation of electronic equipment, such as changing air cooling to self-cooling;

4. No external power supply is required, and no special maintenance is needed when working;

5. Has very good isothermal, after thermal equilibrium, the temperature gradient between the evaporation section and the cooling section is quite small, which can be approximated as 0;

6. The operation is safe and reliable and does not pollute the environment.

+86-18902844286

+86-18902844286

E-mail

E-mail