However, although this type of heat sink has many advantages, you still need to pay attention to its installation direction to ensure the best cooling effect.

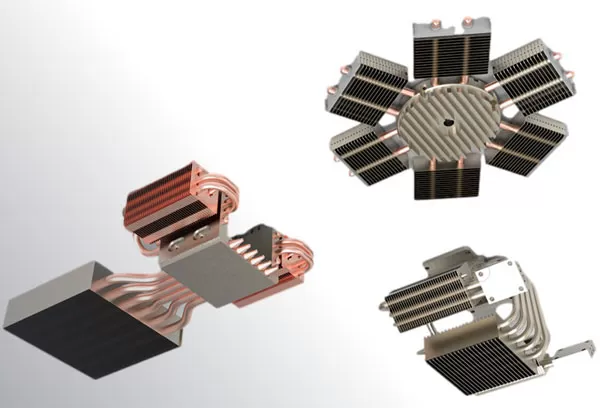

First, let's look at the basic structure of a copper-aluminum composite heat sink. A copper-aluminum composite heat sink consists of copper tubes and aluminum sheets, where the copper tubes are used to transfer the coolant and the aluminum sheets serve to dissipate the heat. agent, while the aluminum plays the role of heat dissipation. The combination of copper and aluminum makes this heat sink have both good thermal conductivity and high strength and corrosion resistance.

When purchasing a copper-aluminum composite heat sink, the first consideration is the direction of installation. Typically, the copper tubes of the heat sink should flow in the same direction as the coolant in the cooling system. direction in the cooling system. This is very important, because if the installation is reversed, it will lead to the coolant can not effectively flow through the heat sink, thus affecting the heat dissipation effect. The heat dissipation effect will be compromised.

To determine the correct orientation of the heat sink, you can refer to the product manual or consult the manufacturer. In the product manual, the inlet and outlet ports of the heat sink are usually clearly labeled. inlet and outlet of the radiator, as well as the direction of coolant flow. Based on this information, you can connect the heat sink to the cooling system correctly and ensure that the coolant flows smoothly through the copper-aluminum composite heat sink. flows smoothly through the copper-aluminum composite radiator for optimal heat dissipation.

In addition to the direction of installation, there are several other aspects to keep in mind. The first is the size and range of application of the heat sink. Different sizes of electronic products may require different sizes of heat sinks to meet the heat dissipation needs, so you need to carefully check the product specifications and the size parameters of the heat sink when shopping and make sure they can be match.

Next is the choice of material. Copper-aluminum composite heat sinks have good thermal conductivity and corrosion resistance, but there are also products of varying quality on the market.

products in the market. In order to ensure that you get a high-quality copper-aluminum composite heat sink, it is recommended that you choose a product from a well-known brand or a reliable supplier, and check the relevant certificates and test reports.

Finally, price is also a factor to consider when shopping. The price of copper-aluminum composite heat sinks varies according to brand, specification and performance.

While determining your budget, it is important to balance the relationship between price and performance, and to choose a product that offers a good price/performance ratio.

In summary, when purchasing a copper-aluminum composite heat sink, you need to pay attention to its installation direction. By correctly connecting the heat sink to the cooling system, ensure that the coolant can smoothly flow through the heat sink to achieve the best heat dissipation effect. In addition, attention should also be paid to the size of the heat sink, material selection and price to ensure that the purchase of a suitable for electronic products. I hope this article will help you in the purchase of copper-aluminum composite heat sink!

+86-18902844286

+86-18902844286

E-mail

E-mail