Aluminum Stacked Fin Heat Sink Product Introduction

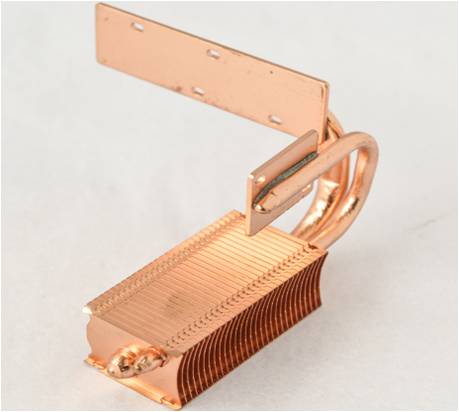

The advantage of the stacked fin heat sink is to form a closed channel while increasing the cooling area, so as to achieve higher thermal performance, not limited by volume, high strength, low manufacturing cost, convenient installation and maintenance, and long service life. Through our technological innovation, PT heat sink has mastered the technology of re-stacking aluminum profiles to produce high-power heat sink. We have a number of mature stacked heat sink production lines.

Aluminum Stacked Fin Heat Sink Process:

1. Make stacked fin by stamping machine

2. CNC machining the base plate

3. Produce heat pipe

4. Stacked fin and base plate nickel plated for soldering process

5. Apply solder paste on base plate groove and fin and assembled by fixture

6. Soldering by reflow oven

7. Cooling down and disassemble the fixture, check stacked fin heat sink is well soldered.

8. On line thermal test

9. Inspection, pack and ship.

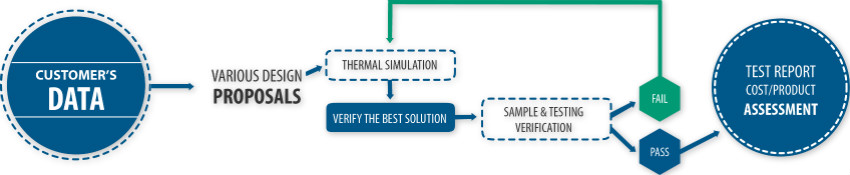

PT can customize stacked fin heat sink based on your thermal requirement and application. More important, we can design stacked fin heat sink and run simulation to find the best and cost reasonable solution for your application.

Design Flow Chart

Custom Soldering Aluminum Heat Sink Supplier, heatsink OEM service. Any heat sinks design and manufacture services, please contact Pioneer Thermal. We'll reply you within 12 hours.

+86-18902844286

+86-18902844286

E-mail

E-mail