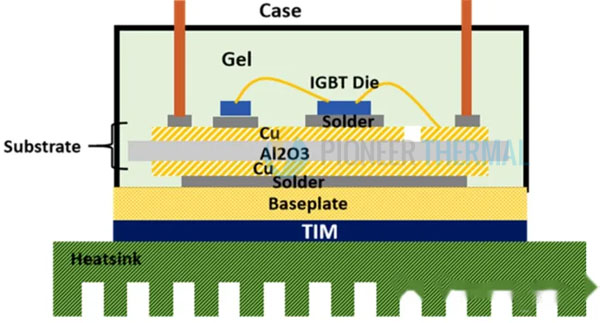

Traditional single-sided cooling power modules have been one of the most common packaging structures in automotive applications. Traditional IGBT power modules mainly consist of IGBT chips, alumina copper-clad ceramic substrates, packaging interconnect materials, bonding wires, electrical connection terminals, etc.

With the development of power electronic devices towards high density, high power and miniaturization, the large-scale use of electronic devices brings convenience to our lives. At the same time, higher and higher power makes the heat dissipation problem of electronic devices more and more serious. Therefore, heat dissipation is a very critical technology, and the quality of heat dissipation directly affects the performance and life of the product.

1. In device packaging, due to different packaging materials, the differences in thermal expansion coefficients of the packaging materials lead to varying degrees of deformation and thermal stress accumulation in the device, eventually leading to detachment of bonding wires, delamination of solder, cracking and delamination of plastic packages, etc. Failure problem; the increase in temperature will also reduce the performance of the device, causing problems such as current load capacity and gate voltage impact. The heat generated by the power chip loss of traditional single-sided heat dissipation is conducted to the radiator in one direction through the insulating substrate and bottom plate. Although this method can solve certain heat dissipation needs, it cannot solve the heat dissipation needs of some large amounts of heat. Using a single-sided heat dissipation solution, the heat transfer channel is limited and the thermal resistance is large, resulting in a large temperature difference between the chip and the heat dissipation surface. During long-term use, the chip is easily burned due to excessive temperature.

2. In traditional power module packaging, the top part of the power semiconductor device is only used for electrical connection, while the bottom part is usually connected to the DBC (direct bonded copper) substrate for electrical connection and heat transfer. Wire bonding has been the interconnect method used in power module packaging due to its ease of use and low production cost. However, this asymmetric packaging structure has a series of defects such as large parasitic electrical parameters and mold bending under thermal stress. Although there have been some improvements in wire bonding technology, including the use of Cu or Al stripline bonding instead of Al, due to higher thermal stress at the connection point and relatively low connection strength, wire bonding is still the key to power module reliability. the weakest link. Lead bonding methods are also a major source of parasitic losses. More importantly, the presence of wire bonds prevents the possibility of heat dissipation from the top of the power semiconductor device.

Advantages of Double-sided IGBT Power Module Heat Sink include:

1. Improved thermal performance will reduce temperature fluctuations and thermal stress within the power module.

2. Eliminating wire bonds also eliminates one of the major failure modes in traditional power module packaging. As a result, the power cycling capabilities and reliability of double-sided cooling modules have been proven to be an order of magnitude higher than single-sided cooling modules, thus extending service life.

3. Improved the electrical performance of the power module. Double-sided cooling of the package requires a planar power package, minimizing the current loop area. This reduces electrical parasitic inductance, optimizing the resistance reduction resulting from larger bonding areas. Wireless bonding configurations are key for silicon carbide devices due to their lower parasitic inductance and higher packaging density.

Pioneer Thermal is a professional custom heat sink manufacturer in the cooling system field. With the goal of providing advanced thermal engineering and design services to customers. If you need IGBT heat sink, please contact us.

+86-18902844286

+86-18902844286

E-mail

E-mail