The water cooling system is generally composed of the following parts: heat exchanger, circulation system, water tank, water pump and water, and heat dissipation structure can be added if required. Because of its physical properties, the thermal conductivity of water is not better than that of metal (fan refrigeration conducts heat through metal), however, the flowing water will have excellent thermal conductivity, that is to say, the heat dissipation performance of the water cooling radiator is proportional to the flow rate of the heat dissipation liquid (water or other liquid), and the flow rate of the refrigerant is related to the power of the water pump of the refrigeration system. Moreover, the heat capacity of the water is large, which makes the water-cooled refrigeration system have a good heat load capacity. This is equivalent to 5 times that of an air-cooled system, and the immediate benefit is that the CPU operating temperature curve is very flat. For example, a system that uses an air-cooled cooler will experience a thermal spike for a short period of time when running a program with a heavy CPU load, or may exceed the CPU warning temperature, while a water-cooled system will have a much smaller thermal fluctuation due to its large heat capacity.

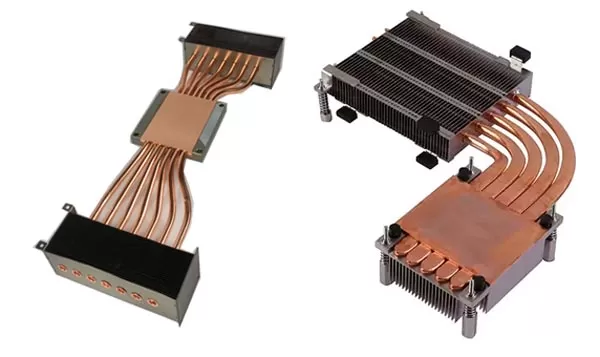

Pioneer Thermal Water Cooling Heat Sink Solution

Multi-process welding processes (high-frequency welding, flame welding, brazing and friction stir welding) are available for all types of water-cooled plates

High precision machining center to meet the production of various types of products

Automatic three-dimensional inspection equipment to ensure that product dimensions meet the requirements of the drawings

Highly sophisticated nitrogen and helium testing equipment to ensure no risk of product leakage

Specialized flow resistance testing equipment to ensure product flow channel stability

Dedicated water-cooled test platform to ensure that the thermal performance of the product meets the requirements

We will assign a sales from China, USA or Singapore, wherever is near you, to get in touch with you.

- Water Cooling Heat Sink

Tags :

+86-18902844286

+86-18902844286

E-mail

E-mail