| Metal | Thermal Conductivity [BTU/(hr·ft⋅°F)] | Density - ρ - (kg/m³) | PricePrice in Price in USD per Metric Ton (20 April, 2018) |

| Aluminum | 136 | 2712 | $2,463.00 |

| Copper | 231 | 8940 | $6,939.00 |

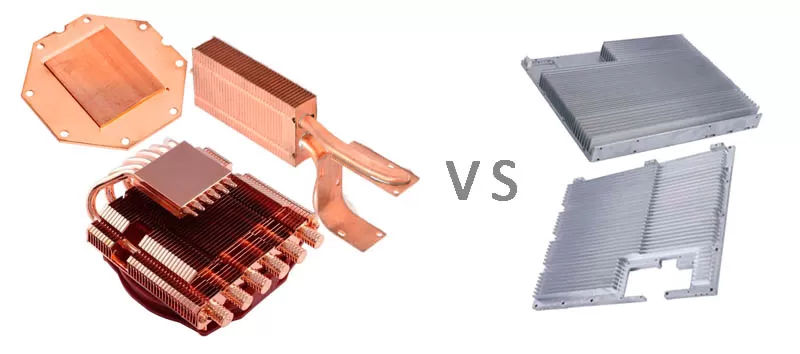

Electronic devices can generate a lot of heat. So, heatsinks play an important role in helping to cool them.You may be aware that aluminum is the most popular metal for heatsinks, but that copper is also sometimes used. You may also realize that copper has better heat conductivity.

Aluminum is Popular for a Reason, But Copper Has Its Place

As you can see, cost and weight savings are key factors in the popularity of aluminum for heatsinks.

Copper heatsinks are available on the market. They can be used in instances where higher heat conductivity outweighs the available weight savings.

The choice between copper and aluminum heat sinks depends on the specific application requirements. Copper heat sinks are better suited for applications that require fast heat transfer and high thermal conductivity. Aluminum heat sinks are better suited for applications that require moderate heat transfer, lightweight solutions, and cost-effectiveness. When choosing between copper and aluminum heat sinks, it is essential to consider factors such as heat dynamics, thermal conductivity, cooling, weight, costs, and availability.

+86-18902844286

+86-18902844286

E-mail

E-mail