Only by exposing the heat as soon as possible can the cavity temperature in the LED lamp be effectively reduced, so as to protect the power source from working in a long-lasting high temperature environment, in order to avoid premature aging of the LED light source due to long-term high temperature operation.

Because the LED light source itself does not have infrared rays or ultraviolet rays, the LED light source itself has no radiation heat dissipation function, and the heat dissipation path of the LED lighting fixture can only derive heat through a heat sink closely combined with the LED lamp bead. The heat sink must have the functions of heat conduction, heat convection, and heat radiation.

Any heat sink, in addition to being able to quickly transfer heat from the heat source to the surface of the radiator, the most important thing is to rely on convection and radiation to dissipate heat into the air. Thermal conduction only solves the heat transfer path, and thermal convection is the main function of the heat sink. The heat dissipation performance is mainly determined by the heat dissipation area, shape, and natural convection strength. Thermal radiation is only an auxiliary function. In general, if the distance from the heat source to the surface of the heat sink is less than 5 mm, then as long as the thermal conductivity of the material is greater than 5, the heat can be derived, and the rest of the heat must be dominated by heat convection.

The following is a comparative analysis of the five types of radiators.

Die casting aluminum heatsinks

The production cost is controllable, the heat dissipation fins cannot be made thin, and it is difficult to maximize the heat dissipation area. LED lamp radiators commonly used die-cast materials for ADC10 and ADC12.

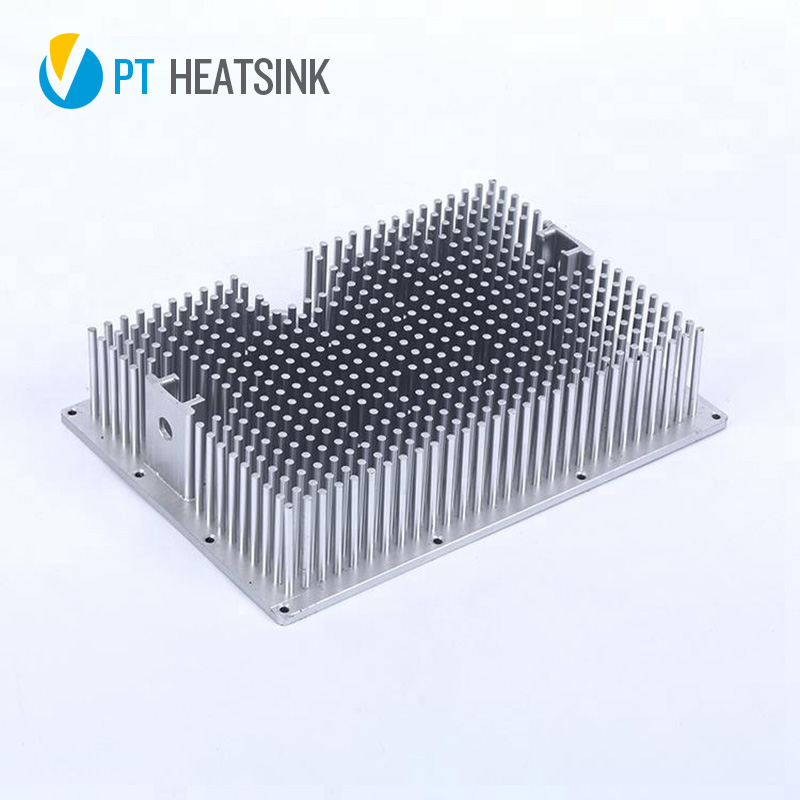

Extruded aluminum heatsinks

The liquid aluminum is extruded through a fixed mold, and then the bar is machined into a heat sink of a desired shape, and the processing cost is high. The extruded aluminum heat sink is shown in Figure 3. The heat dissipating wings can be made a lot of thin, and the heat dissipating area is maximized. When the cooling fins work, the air convection heat is automatically formed, and the heat dissipating effect is better. Common materials are AL6061 and AL6063.

Stamped aluminum heatsinks

The stamping and drawing of steel and aluminum alloy plates are punched and pulled by punching machines and molds to make them into cup-shaped radiators. The inner and outer peripherals of the stamped heat sinks are smooth, and the heat-dissipating area is limited due to the absence of wings. Commonly used aluminum alloy materials are 5052, 6061, 6063. The quality of stamping parts is small and the material utilization rate is high, which is a low-cost solution.

The heat conduction of the aluminum alloy heat sink is ideal, and is suitable for the isolated switching constant current power supply. For non-isolated switching constant current power supply, it is necessary to isolate AC and DC, high voltage and low voltage power supply through the structural design of the luminaire, in order to pass CE or UL certification.

+86-18902844286

+86-18902844286

E-mail

E-mail