Any equipment has a certain loss during operation, and most of the loss becomes heat. Low-power devices have low losses and do not require heat sinks. High-power devices have large losses. If no heat dissipation measures are taken, the temperature of the die can reach or exceed the allowable junction temperature, and the device will be damaged. Therefore, it is necessary to add a heat sink dissipation device. It is very common to install the power device on the heat sink, and use the radiator to dissipate the heat to the surrounding space. If necessary, add a cooling fan to enhance cooling and heat dissipation at a certain wind speed.

Difference in size of electronic heat sink

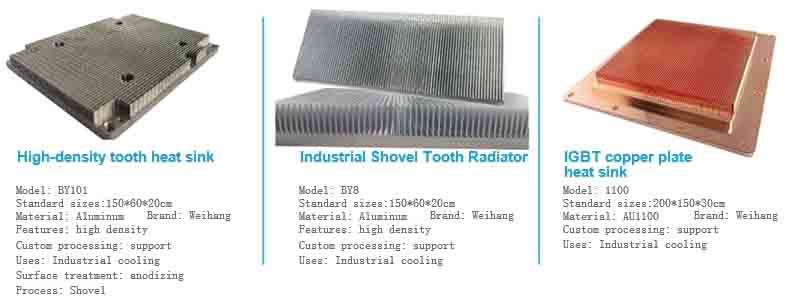

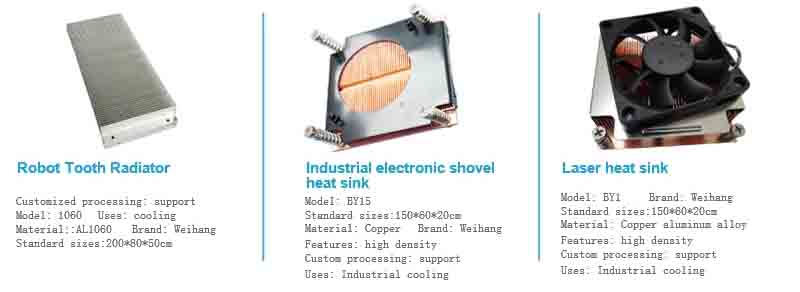

The small electronic radiator is made of aluminum alloy sheet material through stamping process and surface treatment, while the large electronic radiator is extruded from aluminum alloy to form a profile, which is then made by mechanical processing and surface treatment. They come in a variety of shapes and sizes for different device installations and devices with different power consumption. The radiator is generally a standard part, and profiles can also be provided. The user cuts into a certain length according to the requirements to make a non-standard radiator. The surface treatment of the radiator has electrophoretic painting or black oxygen polarization treatment, and its purpose is to improve the heat dissipation efficiency and insulation performance. It can be increased by 1015% under natural cooling and 3% under ventilated cooling, and the electrophoretic coating can withstand 500800V.

+86-18902844286

+86-18902844286

E-mail

E-mail