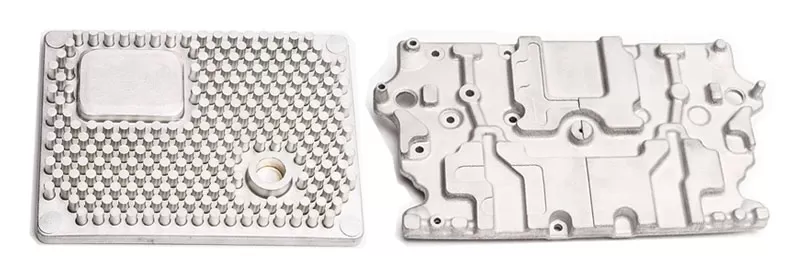

The main component inside the inverter is the IGBT (insulated gate bipolar transistor), and it generates heat. An effective method of cooling the IGBT is through a liquid cooled heat sink.

Forged aluminum alloy and copper heat sinks are particularly suitable, as they have very high thermal conductivity and very good mechanical properties, which contribute to the effective cooling of the system.

Cold forging allows precise dimensions, individual geometries, thin walls and increased part strength, while hot forging is more suitable for structures with complex shapes. This enables Pioneer Thermal to meet the individual needs of customers and benefit from the existing expertise in forged parts.

Our heat sink is available in both aluminum and copper depending upon the customer's requirements. Cooling of IGBT's also has become critical in maintaining reliability and efficiency. These new EV chill plates enhance thermal performance without plugging because the unique shape creates more surface area than a typical straight fin, while still allowing the same sized particles to pass without plugging.

Pioneer Thermal is a leader in EV thermal management and fluid conveyance from our experience with ICE power train systems. We are an established industry partner that offers complete engineering, in house testing and large global production capabilities.

+86-18902844286

+86-18902844286

E-mail

E-mail