○ Understand the Thermal Requirements

Determine the Heat Output: Calculate the total power dissipation of the electronic components.

Operating Temperature Range: Know the acceptable operating temperature range for your components.

Ambient Temperature: Consider the temperature of the environment where the device will operate.

○ Heat Sink Material

Aluminum: Commonly used due to its good balance of conductivity, weight, and cost.

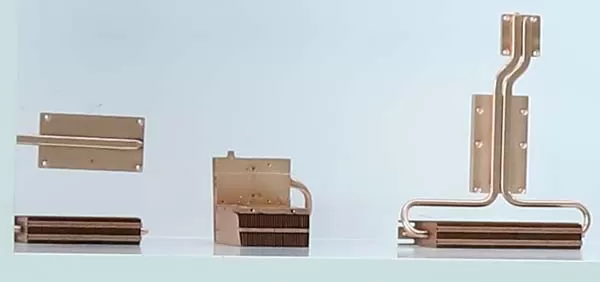

Copper: Offers higher thermal conductivity but is heavier and more expensive than aluminum.

○ Design Considerations

Size Constraints: Measure the available space for the heat sink in your compact electronic device.

○ Fin Design

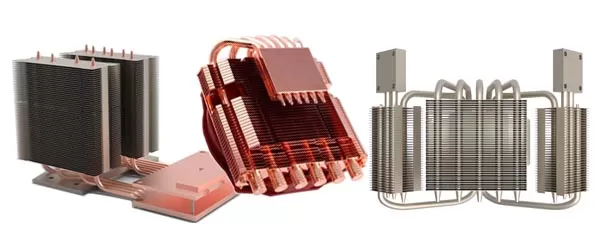

Straight Fins: Suitable for unidirectional air flows.

Pin Fins: Useful in compact spaces with multidirectional air flows.

Flared Fins: Designed to increase surface area and can be effective in limited spaces.

Orientation: The orientation of the fins should align with the airflow direction for maximum heat dissipation.

○ Thermal Interface Material (TIM)

Purpose: TIM improves the heat transfer between the component and the heat sink.

Types: Options include thermal paste, pads, epoxies, and phase-change materials.

Selection: Choose a TIM with the right balance of thermal conductivity and ease of use for your application.

○ Mounting Method

Clip-on: Quick and easy to install, best for light heat sinks.

Adhesive: Good for permanently attaching small heat sinks in compact spaces.

Screw Mounting: More secure, used for larger or heavier heat sinks.

○ Airflow Considerations

Natural Convection: Utilized if the electronics are expected to operate without forced airflow.

Forced Convection: Requires a fan or blower, which can be critical in compact electronics with high power density.

○ Thermal Analysis

Simulation: Use computational fluid dynamics (CFD) software to simulate heat sink performance.

Prototype Testing: Test your heat sink design under actual operating conditions to verify thermal performance.

○ Compliance and Standards

Safety Standards: Ensure the heat sink design complies with relevant safety and performance standards.

EMI Considerations: Make sure the heat sink does not interfere with the device's electromagnetic compatibility.

○ Cost and Availability

Budget: Balance the cost of the heat sink material and design with the required performance.

Supply Chain: Consider the availability and lead times of the heat sink and its materials.

○ Selecting a Manufacturer

Technical Support: Look for manufacturers that offer good technical support.

Custom Solutions: Some applications may require custom heat sink designs.

○ Final Tips

Be prepared to iterate on your design; thermal management can often involve several rounds of design and testing.

Consider the long-term durability of the heat sink, especially in environments with high thermal cycles.

By carefully evaluating these aspects, you can select a heat sink that effectively manages the thermal load of your compact electronics while fitting within the constraints of your device's design and budget.

If you're looking to learn more about Selection Analysis and Suggestion of Heat Sinks for Electronics Devices, need heat sink solution for you, please talk to our team of experts.

+86-18902844286

+86-18902844286

E-mail

E-mail