Combination of low cost and high precision

There are a large number of integrated circuits in electronic equipment such as computers and smart phones. High temperature is the "enemy" of integrated circuits, which will lead to unstable system operation, shortened service life, and may even burn some components. Heat sinks in these electronic devices function to transfer heat away and regulate the temperature of the device. Therefore, the radiator plays a key role in the long-term and stable operation of the equipment. Taking computers as an example, as people's requirements for computing power increase, the requirements for heat dissipation performance of equipment also increase, which poses a challenge to the optimization of heat sink design. and maximized thermal performance.

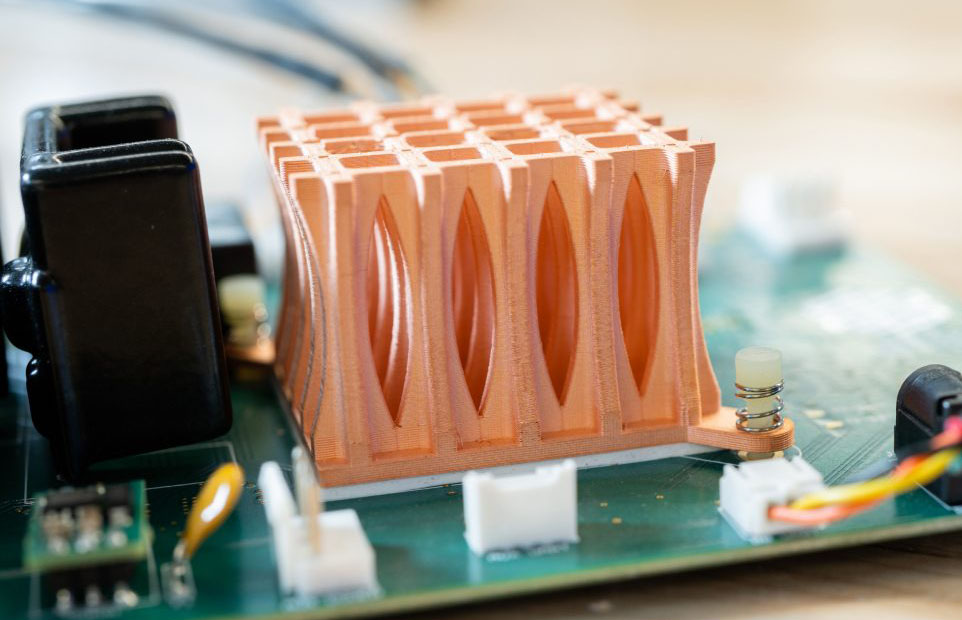

According to market research by 3D Science Valley, the application of additive manufacturing technology, especially metal 3D printing technology in radiator manufacturing, brings a higher degree of freedom to radiator design optimization, 3D printing is used for heat sink or heat exchangers. The manufacturing of the products satisfies the development trend of products becoming compact, efficient, modular and multi-material, especially for special-shaped, structural integration, thin-walled, thin-shaped fins, microchannels, very complex shapes, lattice structures, etc. Processing, 3D printing has advantages that traditional manufacturing techniques do not have.

According to 3D Science Valley's understanding, Pioneer Thermal company from China has realized DLP technology 3D printing copper heat sink parts, and manufactures millions of heat sinks every year.

+86-18902844286

+86-18902844286

E-mail

E-mail