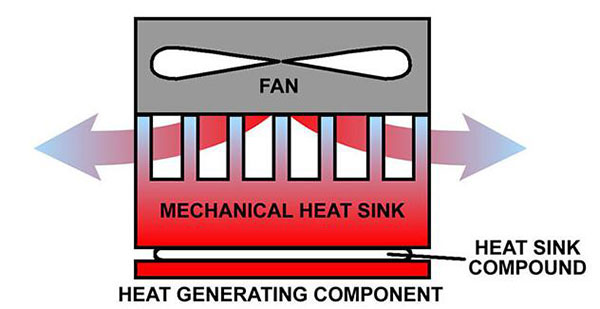

Heat sink compound is used to fill the gap between the CPU (central processing unit) or other heat generating components and the mechanical heat sink. The mechanical heat sink, a passive component made of a conductive metal, is placed over the CPU. Heat is drawn through the mechanical heat sink to its fins, where a fan blows air through to dissipate the excess heat.

Inefficiencies in the thermal transfer occur because two flat surfaces, e.g. CPU and mechanical heat sink, never join together perfectly. Inevitably there is an air gap because of imperfect surfaces. Because air is a relatively bad thermal conductor, this can lead to a reduction in heat dissipation, and as a result, an overheating and failing device. Heat sink compound is used to fill that gap and is designed to efficiently transfer the heat from the heat generating component to the heat dissipating device. Although the heat sink compound does not have the thermal conductivity of metals like copper and silver, the improvement over the air will increase thermal responsiveness.

Heat sink compound does not mechanically connect devices like thermal adhesive. The mechanical heat sink must be firmly attached using screws or other means to minimize the space.

+86-18902844286

+86-18902844286

E-mail

E-mail