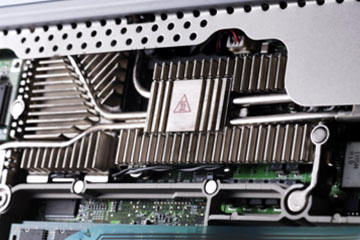

Heat sinks are usually made of metal, which serves as the thermal conductor that carries heat away from the CPU. However, there are pros and cons to using every type of metal. First, each metal has a different level of thermal conductivity. The higher the thermal conductivity of the metal, the more efficient it is at transferring heat.

One of the most common metals used in heat sinks is aluminum. Aluminum has a thermal conductivity of 235 watts per Kelvin per meter (W/mK). (The thermal conductivity number, in this case 235, refers to the metal's ability to conduct heat. Simply put, the higher the thermal conductivity number of a metal, the more heat that metal can conduct.) Aluminum is also cheap to produce and is lightweight. When a heat sink is attached, its weight puts a certain level of stress on the motherboard, which the motherboard is designed to accommodate. Yet the lightweight make up of aluminum is beneficial because it adds little weight and stress to the motherboard.

So where does the heat go once it's been conducted from the processor through the heat sink? A fan inside the computer moves air across the heat sink and out the computer. Most computers also have an additional fan installed directly above the heat sink to help properly cool the processor. Heat sinks with these additional fans are called active heat sinks, while those with the single fan are called passive heat sinks. The most common fan is the case fan, which draws cool air from outside the computer and blows it through the computer, expelling the hot air out of the rear.

+86-18902844286

+86-18902844286

E-mail

E-mail