Whether you are designing electronics, LED lighting, or other computerized objects, you need to think about their thermal management. For the thermal management of mechanical and electrical devices, heat sinks are given priority. Heat sinks got the ability to dissipate the heat out of your devices. Basically, the purpose is to keep your devices cool and efficient.

Thinking about thermal management and heat sinks is not the only thing to do. You have to do enough research to choose a thermal management system that perfectly fits your device. This is why there are multiple types of heat sinks available. Just like their multiple types, there also exist multiple applications for them. The interesting part to know is that these heat sinks are classified according to two categories.

✔By Material Composition

✔By Manufacturing Process

Based on your requirements, you may require heat sinks with different levels of efficiency. For example, it is not necessary that a heat sink efficient for computers will also be efficient for other electrical devices.

Choosing the most efficient heat sink is not rocket science but a matter of good knowledge. In this blog article, you will get to know about different heat sinks types and the factors affecting the efficiency of heat sinks.

Different Types Of Heat Sinks

The main classification of heat sinks is done in two categories. These categories are:

Active heat sinks

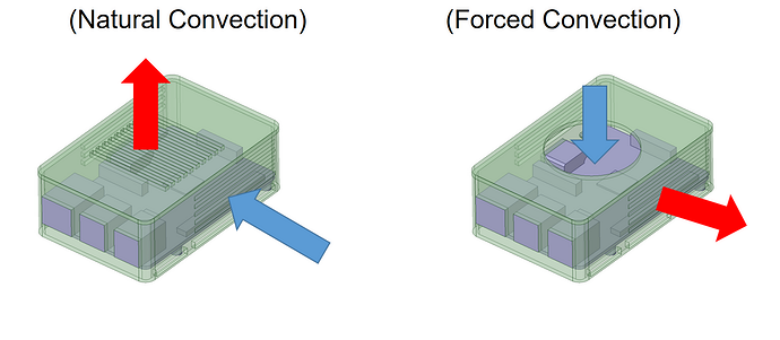

This kind of heat sink contains some kind of blower or fan. Ball bearing motor fan is the most commonly found in active heat sinks. The bad part about them their higher costs. At the same time, they can perform with high efficiency.

Passive heat sinks

These heat sinks don't possess any kind of mechanical parts. The convection process works in these heat sinks for the dissipation of heat. They are known to have higher reliability due to the presence of moving parts.

Analyzing both the types in terms of "efficiency", you will see that active heat sinks tend to be the most efficient. However, due to their high prices, people like to prefer passive heat sinks.

Classification According To Material Composition

In terms of material composition, heat sinks are divided into two main types:

✓Aluminum Heat Sinks

Aluminum heat sinks are used in most projects. It is because of the good thermal conductivity and the lightweight aluminum.

✓Copper Heat Sinks

Copper possesses better thermal conductivity as compared to aluminum, making it more efficient. However, it is weighted and costly.

Analyzing these two categories, you will see that a copper heat sink is more efficient but it is costly. However, it is preferred for projects where weight is not a problem and you can afford the price.

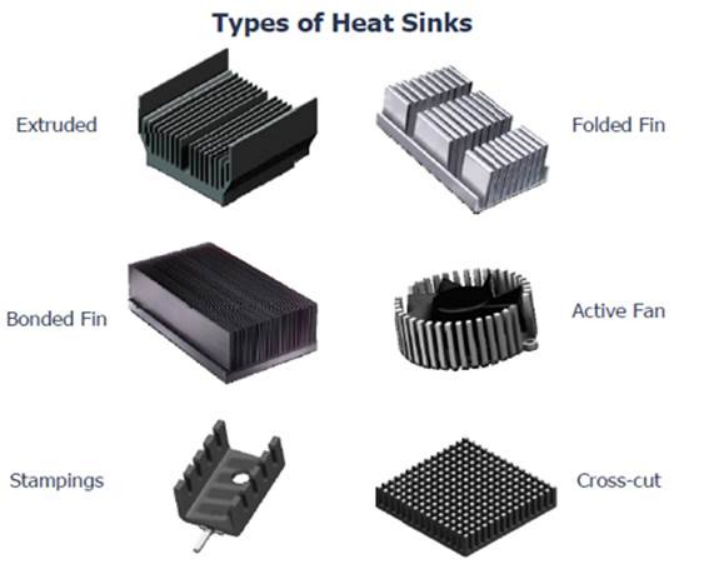

Classification According To Manufacturing Process

Heat sinks are divided into seven categories according to the manufacturing process. These categories are:

●Extruded heat sinks

●Bonded heat sinks

●Skived heat sinks

●Stamped heat sinks

●Forged heat sinks

●Die cast heat sinks

●CNC machined heat sinks

Each of these heat sinks has its own thermal conductivity, weight, cost, and other properties. The most efficient can be the one that perfectly fits your requirements.

Factors Affecting Efficiency Of Heat Sinks

In order to provide efficient functioning of your devices, heat sinks work like a magic in thermal management. However, there are also some factors that affect the efficiency of your heat sinks. The Efficient heat dissipation of your heat sinks largely depends upon how it is designed.

Heat sinks should be designed in a way to allow easy heat dissipation. Usually, it follows radiation, convection, or conduction. Or even sometimes you will see all these processes together in heat sinks.

For efficient heat sinks production, manufacturers take into consideration the following factors:

Thermal Resistance

Thermal resistance in heat sinks resists the heat flow between the surroundings and semiconductors. Note that the surrounding environment can be either a coolant fluid or ambient air.

When selecting the most efficient heat sink, you need to find the thermal resistance of your device. This will help you know how quickly heat can be dissipated.

In other words, you can say that thermal resistance tells about the heat efficiency of the heat sink.

Materials Used

Material Of Heat Sink

As mentioned above, copper and aluminum are the two most commonly used materials for heat sinks. It is because of their good thermal conductivity. Aluminum is cheaper and possesses high ductility, therefore, better for heat sink design.

While copper also possesses good thermal conductivity and high corrosion resistance. You can combine both aluminum and copper for your heat sink designs. It can give you the most efficient heat design.

In most cases, aluminum is known to be a more dominant material for designing heat sinks. But if you want an efficient way then you should combine aluminum and copper for your heat sink design.

Material Of Interface

There is thermal interface material that is used to make space between your heat sinks. There exists air in such a space normally. However, most people also prefer mica in that space.

For your information, the thermal interface material reduces the thermal resistance of your device. As a result, fast heat transfer is ensured.

The heat components of your heat sinks may have varying thermal resistance values. Therefore, you cannot guarantee the effective dissipation of heat.

For efficient heat sink design, you have to reduce the thermal resistance of the device. This is possible only by implementing the thermal interface material.

Arrangement & Shape Of Fins

The efficiency of your heat sinks also depends upon fins arrangement in your heat sinks. Basically, fins orientation provides a space to allow airflow to pass through it. This is why they are considered critical in the process of cooling.

To ensure the effective convection of your heat sinks, you must consider the shape and arrangement of the fins. If you can ensure effective heat dissipation, you can in turn ensure the perfect functioning of your mechanical or electrical device.

Attachment Methods

The efficiency of heat sinks increases positively if you choose an appropriate attachment method. However, you have to think about a few important factors while selecting the attachment Methods. You have to consider requirements such as mechanical and thermal management requirements. On the basis of these requirements, you will be able to decide the most suitable attachment method.

There are multiple methods to attach heat sinks to your devices. Some of those methods are listed below:

✓ Spring-loaded screws

✓Plastic clips

✓Wire clips

✓Thermal tapes

✓Push pins

Consulting with an expert heat sink manufacturer can also help you to choose the most suitable attachment method.

Conclusion

The conclusion comes to the point that selecting the most efficient heat sink is not rocket science. All you need to do is to know about the requirements of your device and design the heat sink accordingly. You have to choose the right material and the right type of heat sink for efficient design.

Moreover, you can use a thermal resistance calculator to know about the thermal resistance of your device. Not every manufacturer considers all these factors while designing your heat sinks. If you are looking for some authentic manufacturing staff to design the most efficient heat sink for you, Contact Us now.

+86-18902844286

+86-18902844286

E-mail

E-mail