You may be aware that aluminum is the most popular metal for heatsinks, but that copper is also sometimes used. You may also realize that copper has better heat conductivity.

So it’s natural to wonder, “If copper has better heat conductivity, why is aluminum so much more common?”

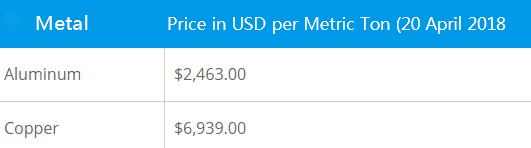

First of all ,copper is more conductive than aluminum. In fact, aluminum only has 60% of the thermal conductivity that copper does but aluminum has only about 30% of the density of copper. That means significant weight savings. Secondly,in fact aluminum is much cheaper than copper, it comes in at about one-third the cost. That is a significant cost savings.

As you can see, cost and weight savings are key factors in the popularity of aluminum for heatsinks.

Copper heatsinks are available on the market. They can be used in instances where higher heat conductivity outweighs the available weight savings.

Also, significant cost savings can be had by producing heatsinks through aluminum extrusion. Most heatsinks are produced this way.If you need heatsink solution,pls feel free to contact us!

+86-18902844286

+86-18902844286

E-mail

E-mail