Although an aluminum heatsink extrusion is not quite as conductive as copper heatsink on its own, it has more than enough additional benefits to make up for it. From a radiation standpoint, aluminum is typically brighter than copper, meaning that it is better at reflecting heat from light sources. This is true even for unpolished aluminum. Also, aluminum can be anodized in a multitude of colors.

Aluminum is inexpensive to manufacture to form an aluminum heat sink extrusion, especially in comparison to copper. It is also incredibly lightweight and easy to manipulate. Both factors make aluminum ideal for larger and custom-configured aluminum heat sink extrusion. These custom configurations are designed from extruded aluminum.

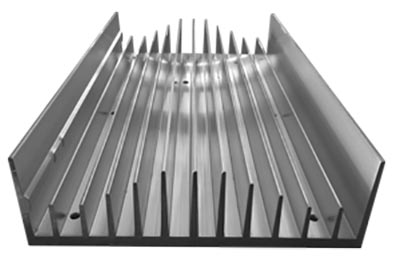

The main functionality of heat sinks depends on the fin arrangement. They are most effective when they cover the greatest possible surface area, so manufacturers design them with multiple layers (aka fins). These fins can use a pin, straight finned extrusion, or flared aluminum heat sink extrusion configurations.

Each of these configurations has its pros and cons. When the airflow is limited, a pin fin heat sink is the most common on the market, providing more surface area for the standard degree of heat transfer. As the heat requirements increase, the fined aluminum heat sink extrusion can offer more economical and more configurations to transfer the heat better. The configurable design of the fins is the best overall for both performance and energy cost.

+86-18902844286

+86-18902844286

E-mail

E-mail