Pioneer Thermal specializing in custom heat sinks designing and manufacturing 18 years.Especially extrusion heat sink, now we'll introduction extrusion heat sink process.

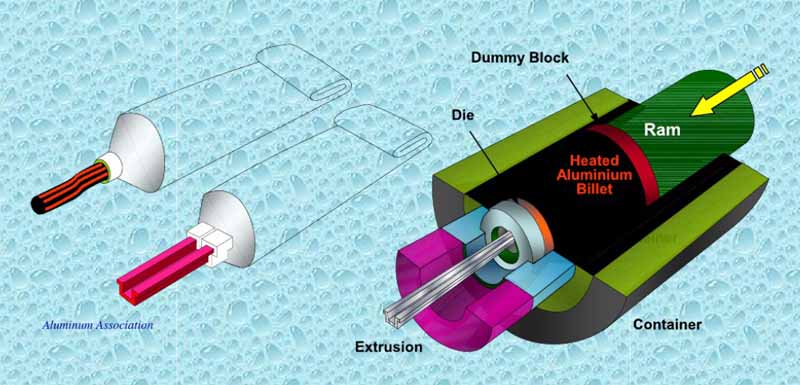

The aluminum round bar is placed on the cutting table, and then sequentially transferred from the conveyor belt to heating furnace for heating. The aluminum bar needs to be heated to a certain temperature (480˚C) before extrusion, and the alloy elements reach the melting point temperature. At the melting point temperature, the alloying element, usually magnesium and silicon begin to melt.

The extrude machine uses the principle of hydraulic pressure to pressurize the ingot barrel to extrude the softened aluminum material through the tool, and the shape of the tool determines the shape of the molded aluminum material.

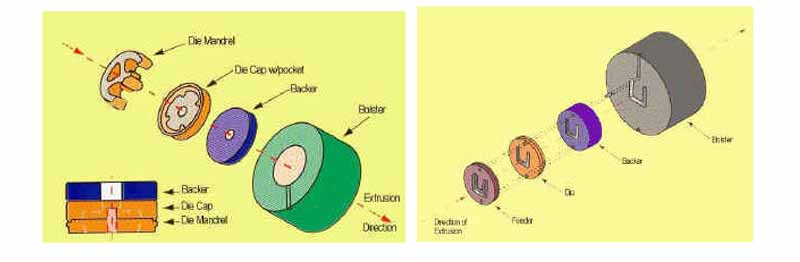

Three main die types of extrusion heat sink

2. Semihollow Die

3. Hollow Die

If you want to custom extrusion heat sink, please send your requirements to [email protected] or contact Mobile/WhatsApp:+86 152 2030 1231.

+86-18902844286

+86-18902844286

E-mail

E-mail