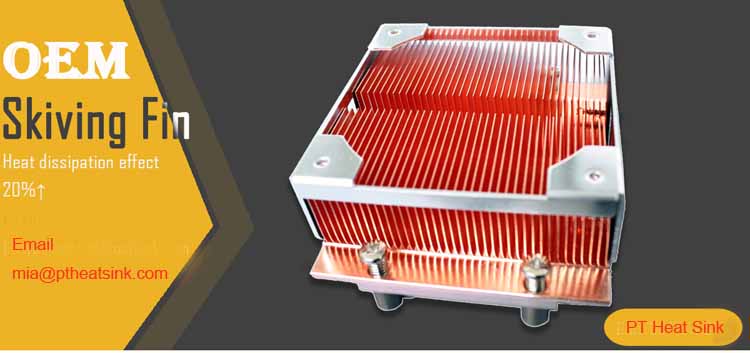

Skive fin/skiving fin is a unique metal forming process. The skived/skiving fin heat sink design concept is that the heat sink is all-in-one without affecting the heat sink coefficient due to welding, so that the heat dissipation can reach the highest value. The method is to use a precisely controlled special planer to cut a piece of metal profile into a thin slice of a specified thickness or numerical control processing technology according to requirements, and then bend it upwards into an upright state to become a heat dissipation fin. Therefore, it has become another popular and mainstream cooling product in the existing cooler market!

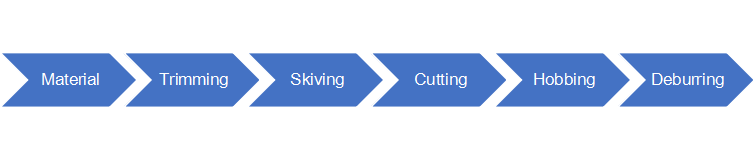

Pioneer Skived/skiving Fin Heat Sink Process:

Advantage:

1.Integrally formed to reduce the contact thermal resistance of the heat sink

2.High fin density

3.Low tooling cost

Disadvantage:

1.Limited size (such as thickness, height)

2.Relatively high price

If you want to custom skiving/skived fin heat sink, please send your requirements to [email protected] or contact Mobile/WhatsApp:+86 152 2030 1231.

+86-18902844286

+86-18902844286

E-mail

E-mail