For the heat sink, the most important thing is that its base can absorb as much heat released by the CPU as possible in a short period of time, that is, the ability to absorb heat instantly. Only metals with high thermal conductivity can be competent. For metallic thermally conductive materials, specific heat and thermal conductivity are two important parameters.

The thermal conductivity is defined as: per unit length, per K, how many watts of energy can be transferred, in W/mK. Where "W" refers to the thermal power unit, "m" refers to the length unit meter, and "K" refers to the absolute temperature unit. The larger the value, the better the thermal conductivity. The following is a table of thermal conductivity of several common metals:

Thermal conductivity (unit: W/mK)

Silver 429 Copper 401

Gold 317 Aluminum 237

Iron 80 Lead 34.8

1070 aluminum alloy 226, 1050 aluminum alloy 209

6063 aluminum alloy 201, 6061 aluminum alloy 155

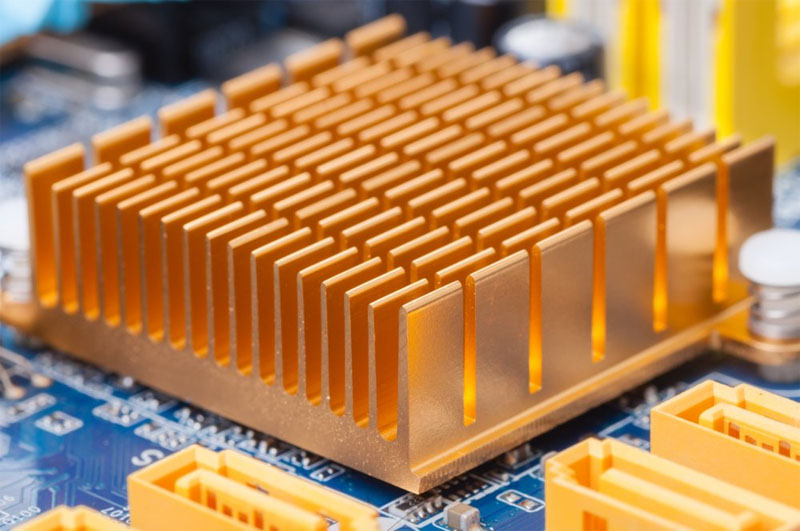

It can be seen that silver and copper are the best thermally conductive materials, followed by gold and aluminum. But gold and silver are too expensive, so heat sinks are mainly made of aluminum and copper. However, due to the high copper density, complex process and high price, the usual fans are mostly made of lighter aluminum. Of course, for the air-cooled heat sink, in addition to the thermal conductivity coefficient, heat dissipation must also be considered when considering the material. The heat capacity of the device, combining these two parameters, the superiority of aluminum is reflected. However, this article only discusses heat transfer aspects, those we will discuss in detail in the next section.

In order to improve the thermal conductivity of the heat sink base, it is on the one hand to choose a material with a higher thermal conductivity coefficient, but on the other hand, it is also necessary to solve the problem of the tightness of the combination of heat sources such as the CPU and the radiator base. According to the law of heat conduction, under the premise that the material is fixed, the conduction capacity is proportional to the contact area and inversely proportional to the contact distance. The larger the contact area, the faster the heat can be dissipated, but the die is fixed for the CPU, so the bonding distance is more important.

Although theoretically, the heat sink base can be in close contact with the CPU, but objectively speaking, no matter how smooth the two contact surfaces are, there is still a gap between them, that is, there is air, and the thermal conductivity of air is very poor. , which requires an excellent design and strong grip to fasten the heat sink tightly to the CPU. In addition, it is necessary to replace the air with something with better thermal conductivity and deformability to fill these gaps, such as thermal grease or Thermal tape. The ideal situation is that the heat sink is tightly fixed to the CPU, the contact between the heat sink and the CPU is completely parallel to keep the contact area as large as possible, and some tiny gaps between them are completely filled with silicone grease to keep the contact thermal resistance to a minimum.

However, it must be made clear that no matter what kind of thermal grease or thermal tape, its function can only be auxiliary, and its thermal resistance is many times larger than that of the copper heat dissipation base material. In order to maximize the thermal conductivity of the heat sink base, it is necessary to ensure that the heat sink base is smooth and flat, so that the gap between the heat sink and the CPU contact surface can be truly reduced.

+86-18902844286

+86-18902844286

E-mail

E-mail