1. Importance

In the photovoltaic industry, solar panels generate a certain amount of heat in the process of converting solar energy into electricity. If this heat is not dissipated in time, it will cause the temperature of the panel to rise, which will reduce its power generation efficiency and service life. Therefore, efficient heat sinks are essential for the stable operation of photovoltaic systems.

2. Features

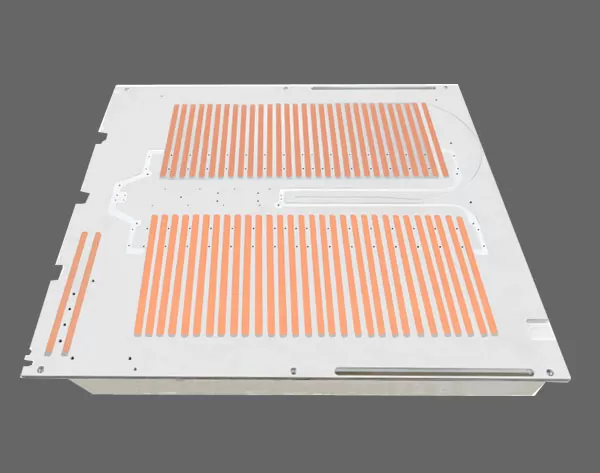

High-density tooth heat sink: Compared with the traditional shovel tooth heat sink, the photovoltaic new energy high-density shovel tooth heat sink has a higher tooth density. This allows for a larger heat dissipation area and more efficient heat dissipation.

Optimized material selection: Metal materials with high thermal conductivity, such as aluminum alloy, copper, etc., are usually used to ensure that heat can be quickly conducted to the heat sink and dissipated.

Good weather resistance: Since photovoltaic systems are usually installed in outdoor environments, heat sinks need to have good weather resistance and be able to resist the erosion of natural factors such as ultraviolet rays, sandstorms, and rain.

Lightweight design: On the premise of ensuring heat dissipation performance, the weight of the heat sink is reduced as much as possible to facilitate installation and maintenance.

3. The working principle

Similar to ordinary shovel tooth heat sinks, photovoltaic new energy high-density shovel tooth heat sinks also dissipate heat through heat conduction and heat convection. The heat generated by the solar panels is first conducted to the heat sink and then dissipated into the surrounding environment through the contact of the teeth with the air. At the same time, the flow of air will also take away the heat on the teeth, further improving the heat dissipation efficiency.

4. Application scenarios

It is mainly used in various photovoltaic power stations, distributed photovoltaic power generation systems and solar water heaters and other photovoltaic related equipment. In these applications, high-density shovel tooth heat sinks can effectively reduce the temperature of solar panels and other critical components, improving the power generation efficiency and reliability of the system.

5. Advantages

Improve the efficiency of the photovoltaic system: By reducing the temperature of the panels, the impact of temperature on the power generation efficiency is reduced, so as to improve the overall power generation efficiency of the photovoltaic system.

Extend the life of the equipment: Good heat dissipation performance can reduce the working temperature of the equipment, reduce the damage of thermal stress to the equipment, and prolong the service life of solar panels and other key components.

Adapt to different environments: The strong weather resistance makes it able to adapt to a variety of harsh outdoor environments, ensuring that the photovoltaic system can operate stably under different climatic conditions.

Energy saving and environmental protection: Efficient heat dissipation performance can reduce the demand for auxiliary heat dissipation equipment such as air conditioners, reduce energy consumption, and meet the requirements of energy conservation and environmental protection.

Pioneer Thermal Heatsink was established in 2003 in China with the goal of providing advanced thermal engineering and design services to customers. We specialize in the design and manufacturing of high quality, high performance but cost effective heat sinks manufacturer, which are widely used in the field of consumer electronics, Led, power, medical, telecommunications and automotive industries.

+86-18902844286

+86-18902844286

E-mail

E-mail