Vacuum brazing is a liquid phase process, whereby molten filler metal is drawn into the gap between closely adjacent surface by capillary attraction

Vacuum Brazing means brazing process happens in the vacuum condition.

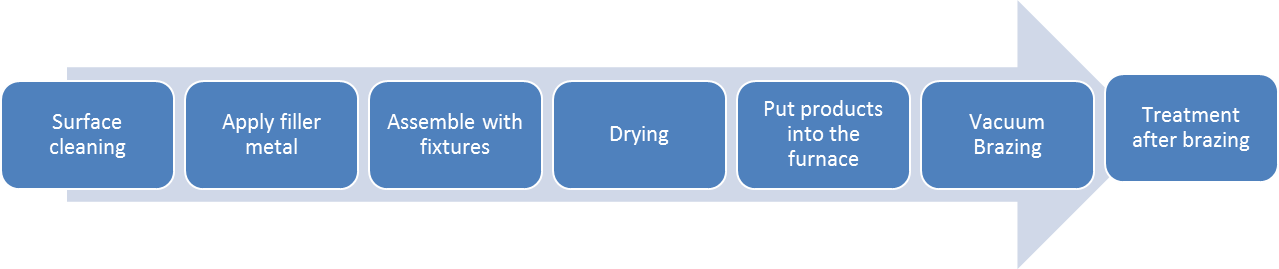

Vacuum Brazing Heat Sink Process Flow:

Surface Cleaning

Remove Oil on heat sink

Removing the oxide, burrs,scraps on heat sink

Vacuum brazing heat sink surface requirement:

Flatness ≤0.2mm

Roughness ≥3.2um

Filler Metal--The melting temperature must be below the solidus temperature of base material.

Normal filler metal for Al Brazing( AL 4047 is better using on Al 6063 brazing)

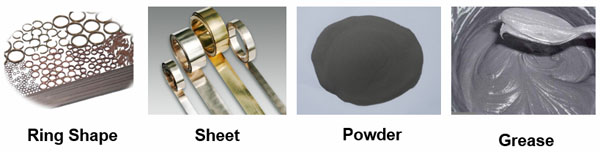

Shape of filler metal

Assemble with Fixtures—The brazing fixtures should ensure close coordination between the surface needs to be brazed.

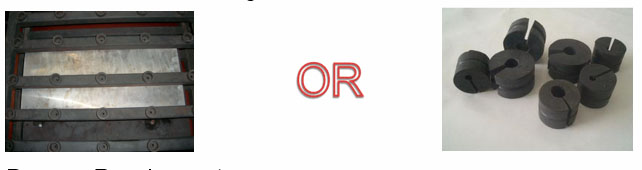

Fixtures:

Special fixtures with Springs which can withstand high temperature

Balance weight

Process Requirements

Fixture material can withstand the brazing temperature, without loss of strength, no deformation and no alloy reaction happens;

Ensure appropriate gap between the brazing surface under brazing temperature

Fixture to ensure the heat transfer on brazing area, minimal interference to the brazing process which caused by fixtures heat transfer

Drying

If using the powder filler metal or the solder paste, should put the products into oven drying for 10~20min or natural drying at the room temperature for 1H, then scrap the excess filler metal

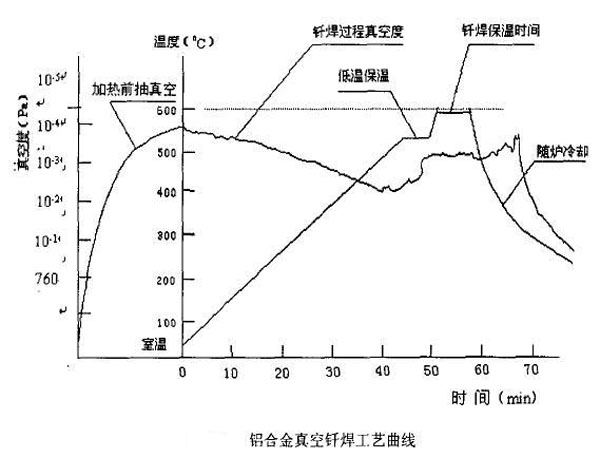

Vacuum Brazing

Vacuum brazing heat sink requirements:

Products should be placed in the area where temperature is closed, to avoid products uneven heating, stress and deformation

Ensure furnace vacuum controlled in the 10-3Pa when brazing

Treatment after vacuum brazing process

mainly clean the inside water channel of heat sink

Sometimes heat treatment to increase the heat sink mechanical strength after brazing.

+86-18902844286

+86-18902844286

E-mail

E-mail