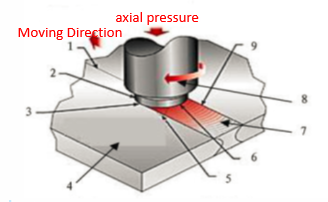

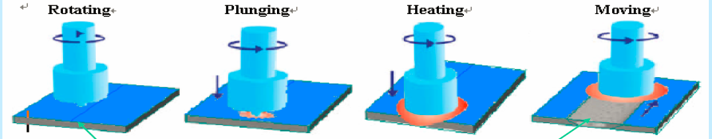

The friction stir welding is a new development of friction welding method, it can reliable join for varied weld ability poor nonferrous metal and other material. The joint technology is simple and technology adaptability is quite good in the friction stir welding. Different material can be FSW together, such as die cast ADC12 can be FSW to AL6063.

1.Joint

2.The front edge of stir drill bit

3.Advance side

4.Base metal

5.Stirring pin

6.The trailing edge of stir bit

7.Welding line

8.Direction of rotation

9.Retreating side

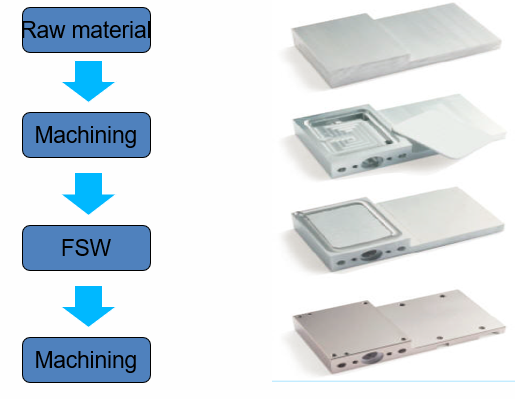

Cold Plate working process:

Friction Stir Welding (FSW) cold plate has below Advantages compared to other processes of cold plate:

l Automation of welding

1.Similar to the CNC machine’s working process

2.Need compress the welding workpieces

3.Don't rely on welder’s skills

4.Automatic welding process

l Little deformation & Little Shrinkage

Cold plate process comparison

Process

Epoxy Bonding

Vacuum Brazing

Gun Drilling

FSW

Item

Cost ranking

Higher

Highest

Highest

Moderate

Tooling ranking

Higher

Higher

Lowest

Moderate

Develop ranking

25-30 days

30-35 days

7-14 days

10-14 days

Performance ranking

Lower

Highest

Lower

Moderate

Reliability

100 PCS

50 PCS

50 PCS

50 PCS

Dimension

(comparison base on)

Length:320mm

Length:320 mm

Length:320 mm

Length: 320 mm

Width: 300 mm

Width: 300 mm

Width: 300 mm

Width: 300 mm

Thickness: 22mm

Thickness:20 mm

Thickness:20 mm

Thickness: 20 mm

Weight

5.0 – 5.3 Kg

5.0 – 5.3 Kg

5.0 – 5.3 Kg

5.0-5.3Kg

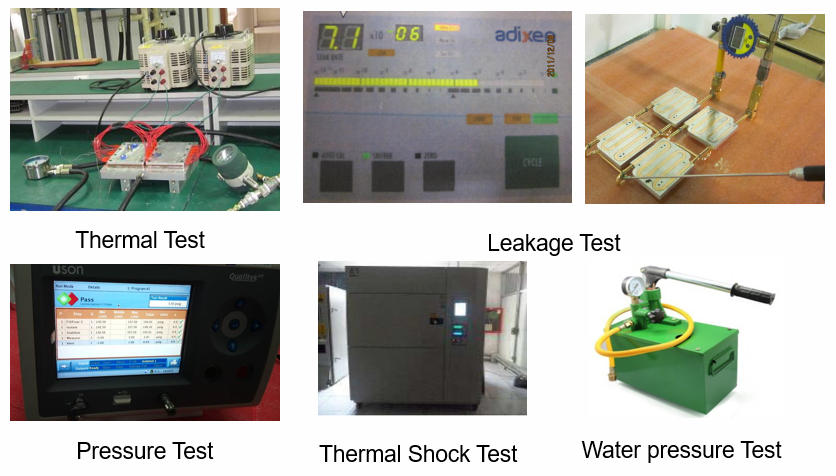

Cold Plate Reliability Test from Pioneer Thermal:

Pioneer Thermal can provide various size and shape of cold plate, contact us for details!

+86-18902844286

+86-18902844286

E-mail

E-mail