Different parts of the bonded fin heat sink are connected by welding. The quality of welding directly affects the quality and service life of the plug-in radiator. The welding processes mainly include filler welding and body welding. Relatively speaking, body welding has good corrosion resistance and has a uniform weld scar, which does not require grinding. Filler welding has poor corrosion resistance and the surface is smooth and flat after grinding.

When purchasing, mainly look at whether the welding is firm, whether the appearance of the weld is uniform, and whether there is any unevenness. However, do not force the smoothness of the weld too much, because excessive grinding can easily reduce the strength of the welded part and cause water leakage.

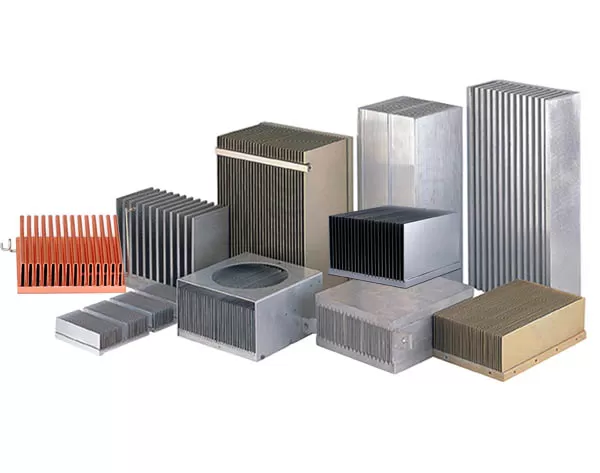

Production procedures of bonded fin heat sink

1. When testing molds with high-density teeth and large tongue ratios, the first aluminum rod must be a short aluminum rod or pure aluminum rod of 150-200mm.

2. Before testing the mold, the extrusion center must be adjusted, and the extrusion axis, ingot barrel and die base outlet must be on a center line.

3. During the mold trial and normal production process, the heating temperature of the aluminum rod must be guaranteed to be between 480-520℃.

4. The mold heating temperature is controlled at about 480℃ according to the conventional mold temperature. The insulation time of flat molds with a diameter of less than 200mm shall not be less than 2 hours. If it is a split mold, the insulation time shall be more than 3 hours; the mold with a diameter greater than 200mm shall be insulated for 4-6 hours to ensure the uniformity of the mold core temperature and the external temperature.

5. Before the mold trial or production, the inner liner of the ingot barrel must be cleaned with a cylinder cleaning pad, and the extruder must be checked for normal empty operation.

6. When testing the mold or just starting production, the extruder is automatically turned off and the switches of each section are reset to zero. Start from the minimum pressure and slowly pressurize. It takes about 3-5 minutes to discharge the material. The main thing to do during the aluminum filling process is to control the pressure. The pressure is controlled within 100Kg/cm2, and the ammeter data is within 2-3A. Generally, 80-120Kg/cm2 can discharge the material, and then it can be slowly accelerated. During normal production, the extrusion speed is based on a pressure less than 120Kg/cm2.

7. During the mold trial or production process, if the mold is blocked, the teeth are offset, the speed deviation is too large, etc., the mold must be stopped immediately, and the mold must be unloaded by point retreat to avoid mold scrapping.

8. During the mold trial or production process, the discharge port must be unobstructed, and the pad support or clamp loosening should be reasonably controlled according to the discharge situation. Observe and find abnormal conditions at any time, deal with them in time, and stop the machine immediately when it is time to stop.

9. During the straightening process, carefully check the changes before and after, operate in a standardized manner, use moderate force, and strictly ensure product quality.

10. Reasonably set the length according to the production plan. When sawing, the saw teeth should not be fed too fast to avoid damaging the end. The end must be clamped straight and the flash and burrs must be removed.

11. The basket should be loaded in a standardized manner, including the pads should be placed reasonably to avoid damaging the profile.

12. The aging temperature of the profile is controlled at 190±5℃, kept warm for 2.5-4 hours, and air-cooled after leaving the furnace.

+86-18902844286

+86-18902844286

E-mail

E-mail