The heat sink structure of the LED street light module is in a plane match with the LED street light module, which is easy to cause gaps due to poor fastening, affecting the sealing and waterproof properties of the heat sink structure and the LED street light module. Therefore, in order to solve this problem, more and more companies insist on taking the road of innovation. At present, the solutions seen on the market generally have the following two methods:

1. Increase the overall thickness of the bottom plate of the LED street light module heat sink. This method increases the weight and volume of the LED street light module heat sink

2. Add bosses locally at the blind hole, but due to different requirements for the LED street light module radiator, the position of the fixed point is also different, which requires adding bosses to the radiator in different places. This method has poor versatility and high cost, and the existing bottom plate and fins are both flat structures with weak structural strength and easy to damage.

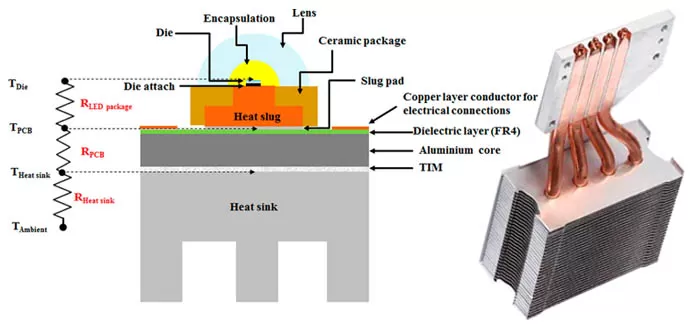

The LED heat sink module of street light consists of a base plate and fins arranged on the base plate. In the process of developing and producing LED street light module heat sinks, Pioneer Thermal made adjustments in the design and production process in order to ensure the sealing of the heat sink to a certain extent. By setting a straight rib on the base plate and setting a blind hole on the rib, the sealing and waterproof properties of the heat sink can be ensured. The sealing ring can also further improve the waterproofness and sealing between the base plate and the LED light module. Since the position of the blind hole on the rib can be adjusted according to different installation requirements, it is helpful to make the base plate universal, reduce the development of base plate molds, and reduce costs.The columnar structure is set on the fin, which can well support the fin, improve the strength of the fin, and prevent the fin from deformation, so that it achieves the effect good sealing of LED heat sink.

+86-18902844286

+86-18902844286

E-mail

E-mail